What is the difference between concentrated winding and distributed winding of a motor?

The windings of the motor can be divided into concentrated windings and distributed windings. In case of distributed windings, the winding is always wound on at least two stator teeth. On the other hand, in case of concentrated windings, only one stator tooth is wound. Both types of windings have different advantages and disadvantages. When to use concentrated windings and when to use distributed windings depends on the size of the motor and its application. The number of tooth slots and the way the motor is manufactured also affect the choice of winding type. The characteristics that are important for winding design are fractional slot windings and integer slot windings, as well as single-layer windings and double-layer windings.

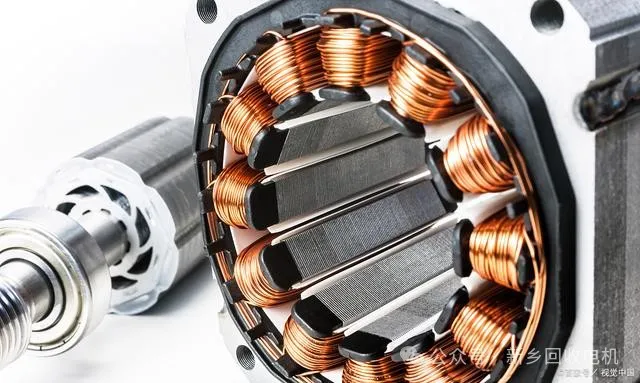

Concentrated Winding

With concentrated winding, the stator is always wound on exactly one tooth, which has significant advantages in the manufacture of the stator. For example, the already completed winding can simply be pushed onto the stator, for which the design of the stator teeth has to be designed. A major advantage of concentrated winding is that the winding heads at the top and bottom of the motor are very small. In distributed winding, this winding head is larger due to the overlapping of the windings. Due to the smaller winding heads of concentrated winding, the ohmic losses in the lower speed range are lower for distributed windings.

When using the classic design of a motor with concentrated winding development, the back EMF is trapezoidal, therefore, this type of winding can produce high torque, especially in the lower range, which does not mean that it also leads to high efficiency. This is because the main disadvantage of concentrated windings is the generation of harmonics, which lead to high losses, especially at high speeds, these losses can occur in the windings of the laminations as well as in the permanent magnets.

Concentrated windings are mainly used for short, large-diameter motors, an example of this being the hub drive of an e-bike without gears. Concentrated windings are also used in drives where high dynamics are required and efficiency is not so critical. Another disadvantage of concentrated windings is that the torque ripple is not insignificant, which can be compensated by moving the magnets on the rotor relative to each other or by correspondingly shaped magnets.

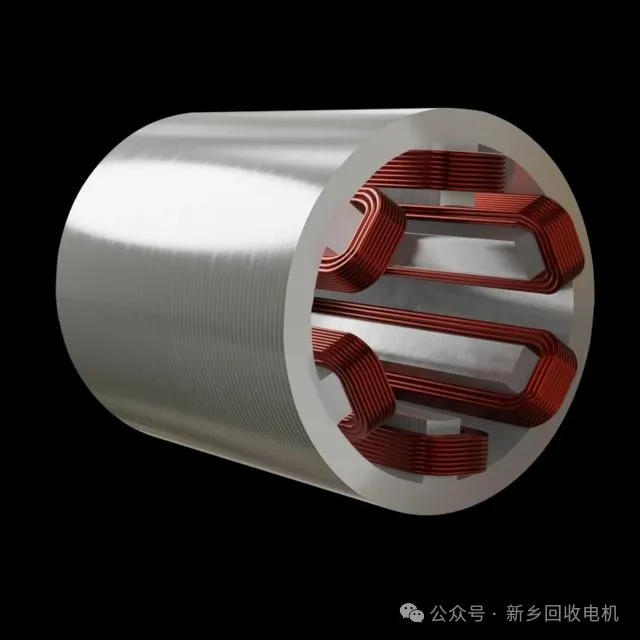

Distributed winding

For distributed windings, at least two teeth of the stator are always wound, as shown in the example in the figure below. The number of teeth wound is called the coil pitch or step size, but 3, 4, 5 or more teeth can also be wound. In distributed windings, the windings overlap at the top and bottom of the motor. This area of the motor is also called the winding head. Due to the overlap, the winding heads in distributed windings are larger than those in concentrated windings. Therefore, for very short motors, concentrated windings are usually used instead of distributed windings, which allows to reduce the ohmic losses in the winding heads.

For longer motors, the effect of the winding head losses is not significant compared to the total losses. A very important advantage of the distributed winding of the motor is that the generated back EMF has a smooth, mostly sinusoidal character. This means that the proportion of harmonics is very low and the losses in the stator and winding laminations are also very low. Distributed windings are used where high efficiency is required, such as in electric vehicles. Another advantage of distributed windings is the high synchronicity, which means that the torque ripple and the noise of the motor are very low. Therefore, distributed winding motors are mainly used in rotary spindles of machine tools, otherwise the torque oscillations will have a negative impact on the quality of the workpiece being machined.

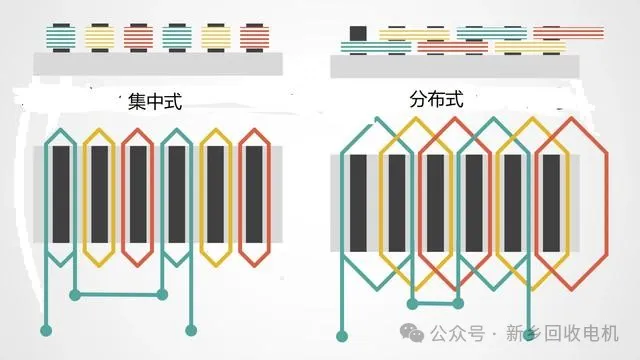

Motor winding diagram

In concentrated winding, one tooth of the stator carries exactly one winding. Different colors represent the three phases U, V, and W. The two windings of one phase are connected to each other. The three phases can be connected in star or triangle. In distributed winding, at least two teeth are wound, as shown in the figure below. The number of teeth wound is called the coil span. Of course, 3, 4, 5 or more teeth can be wound. The coil span depends on the number of teeth of the stator and the number of pole pairs of the rotor.

Distributed winding and concentrated winding

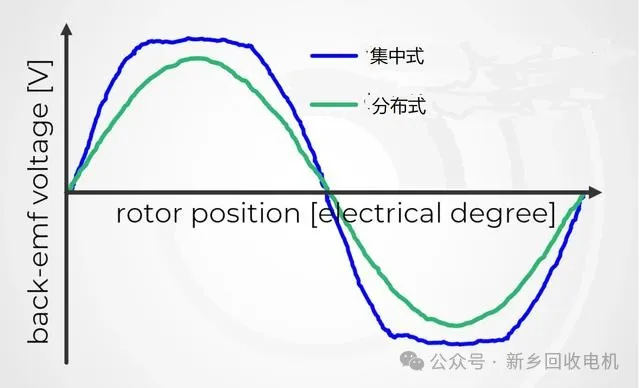

What is the technical difference between distributed winding and concentrated winding, for this we need to measure the voltage of the back EMF. This is the voltage that can be measured at the terminals of a motor with permanent magnets when the motor is rotated by hand or a load machine at a fast enough speed. In the figure below, you can see that the voltage of the motor with distributed winding is sinusoidal, on the other hand, the back EMF of the concentrated winding is trapezoidal.

What does this mean for the performance of the motor? Using a motor with concentrated windings, more torque can be produced due to the trapezoidal back EMF. However, the losses in the copper wire and laminations are greater because there are more and higher harmonics. Using distributed windings, higher efficiency can be achieved due to the sinusoidal back EMF, which is especially important for electric vehicles. This does not directly mean that if a motor has a sinusoidal back EMF, the motor has high efficiency. Motors using concentrated windings can also achieve the sinusoidal nature of the back EMF by adjusting the rotor design.

XINDA

XINDA