3 Servo Motor Control Methods Every PLC Engineer Should Know

The servo motor speed control and torque control are both controlled by analog quantity, and the position control is controlled by sending pulses. The specific control method should be selected according to the customer's requirements and the motion function to be met.

Next, I will introduce three control methods of servo motors:

-

If you have no requirements for the speed and position of the motor and just want to output a constant torque, of course you should use the torque mode.

-

If you have certain accuracy requirements for position and speed, but are not very concerned about real-time torque, it is better to use speed or position mode.

-

If the upper controller has a relatively good closed-loop control function, the speed control will be better. If the requirements are not very high, or there is basically no real-time requirement, the position control method does not have very high requirements for the upper controller.

In terms of the response speed of the servo drive: the torque mode has the smallest amount of calculation, and the drive responds to the control signal the fastest; the position mode has the largest amount of calculation, and the drive responds to the control signal the slowest.

When there are relatively high requirements for dynamic performance during movement, the motor needs to be adjusted in real time.

-

If the controller's own computing speed is very slow (such as PLC, or low-end motion controller), use position control.

-

If the controller operates at a relatively fast speed, the position loop can be moved from the driver to the controller in a speed-controlled manner to reduce the driver's workload and improve efficiency.

-

If there is a better upper controller, it can also use torque control and move the speed loop away from the drive. This is generally only possible with high-end dedicated controllers.

Generally speaking, there is a more intuitive way to compare the quality of driver control, called response bandwidth .

When torque control or speed control is performed, a square wave signal is given to it through the pulse generator to make the motor rotate forward and reverse continuously and continuously increase the frequency. What is displayed on the oscilloscope is a swept frequency signal. When the top of the envelope reaches 70.7% of the maximum value, it means that it has lost step. The frequency at this time can explain the quality of control. Generally, the current loop can reach more than 1000HZ, while the speed loop can only reach tens of Hz.

The torque control method is to set the size of the motor shaft's external output torque through the input of external analog quantity or direct address assignment. For example, if 10V corresponds to 5Nm, when the external analog quantity is set to 5V, the motor shaft output is 2.5Nm: if the motor shaft load is less than 2.5Nm, the motor rotates forward, when the external load is equal to 2.5Nm, the motor does not rotate, and when it is greater than 2.5Nm, the motor reverses (usually generated under gravity load conditions). The set torque size can be changed by instantly changing the analog quantity setting, or by changing the corresponding address value through communication.

It is mainly used in winding and unwinding devices that have strict requirements on the stress of the material, such as wire winding devices or optical fiber pulling equipment. The torque setting should be changed at any time according to the change of the winding radius to ensure that the stress of the material does not change with the change of the winding radius.

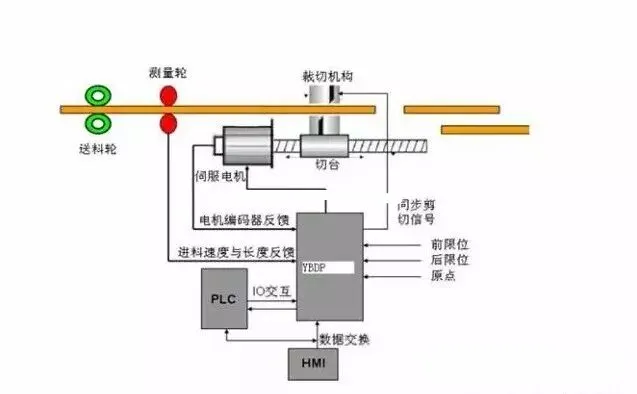

The position control mode generally determines the rotation speed by the frequency of the external input pulse, and the rotation angle by the number of pulses. Some servos can also directly assign speed and displacement through communication. Since the position mode can have very strict control over both speed and position, it is generally used in positioning devices.

Application areas include CNC machine tools, printing machinery, etc.

The rotation speed can be controlled by analog input or pulse frequency. The speed mode can also be used for positioning when there is an outer loop PID control of the upper control device, but the motor position signal or the direct load position signal must be fed back to the upper control device for calculation. The position mode also supports direct load outer loop detection of position signals. At this time, the encoder at the motor shaft end only detects the motor speed, and the position signal is provided by the detection device at the direct final load end. This has the advantage of reducing the error in the intermediate transmission process and increasing the positioning accuracy of the entire system.

Servo motors are generally controlled by three loops, which are three closed-loop negative feedback PID adjustment systems. The innermost PID loop is the current loop, which is completely performed inside the servo drive. The Hall device detects the output current of each phase of the motor from the drive, and negatively feeds back the current setting for PID adjustment, so that the output current is as close to the set current as possible. The current loop controls the motor torque, so the drive operation is minimal and the dynamic response is fastest in torque mode.

The second loop is the speed loop, which performs negative feedback PID adjustment through the detected signal of the motor encoder. Its in-loop PID output is directly the setting of the current loop, so the speed loop control includes the speed loop and the current loop. In other words, any mode must use the current loop. The current loop is the basis of control. While controlling the speed and position, the system is actually also controlling the current (torque) to achieve corresponding control of the speed and position.

The third loop is the position loop, which is the outermost loop. It can be built between the driver and the motor encoder, or between the external controller and the motor encoder or the final load, depending on the actual situation. Since the internal output of the position control loop is the setting of the speed loop, the system performs calculations on all three loops in the position control mode. At this time, the system has the largest amount of calculations and the slowest dynamic response speed.

XINDA

XINDA