How to select the measurement points when measuring motor vibration?

Motor vibration measurement should be carried out without external interference. According to GB10068, vibration measurement requires that the rotating motor be separated from any load and prime mover and be carried out under specified conditions to directly reflect the state of the motor itself. The measurement results under operating conditions will be affected by equipment and load interference, causing the measurement results to deviate from the actual state of the motor.

The motor vibration measurement points may vary according to the actual structural characteristics, but the core points are all centered around the bearings, measured in three directions: horizontally, vertically, and axially. When interference occurs, they will be moved away appropriately but should be as close to the bearings as possible.

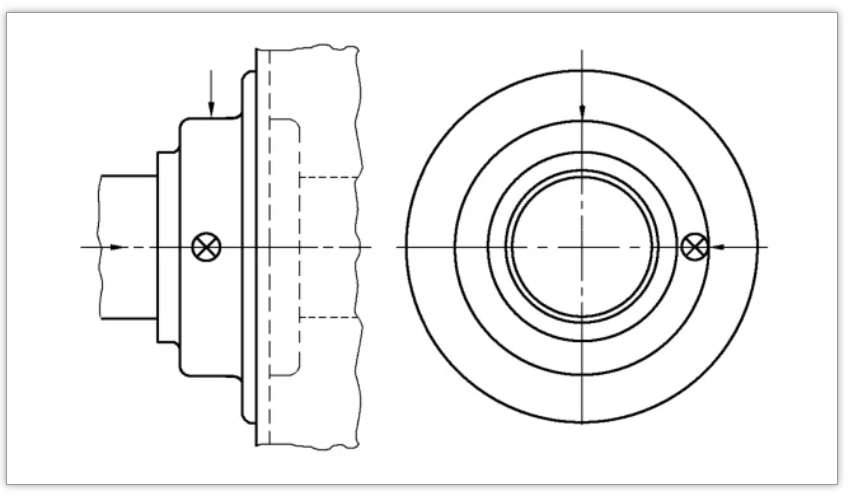

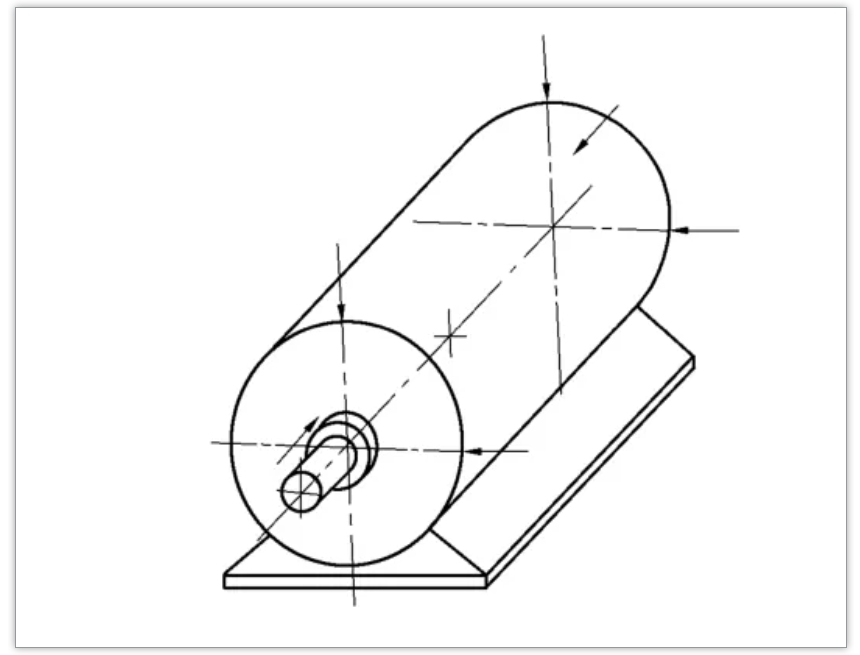

For end cover bearing motors, the axial measurement is on the bearing cover, and the vertical and horizontal measurement points are on the end cover as specified in Figure 1. When there is interference between components, measurement is performed as specified in Figure 2. In this state, the measurement point may be on the machine base, but the point should be selected as close to the bearing as possible.

Figure 1

Figure 2

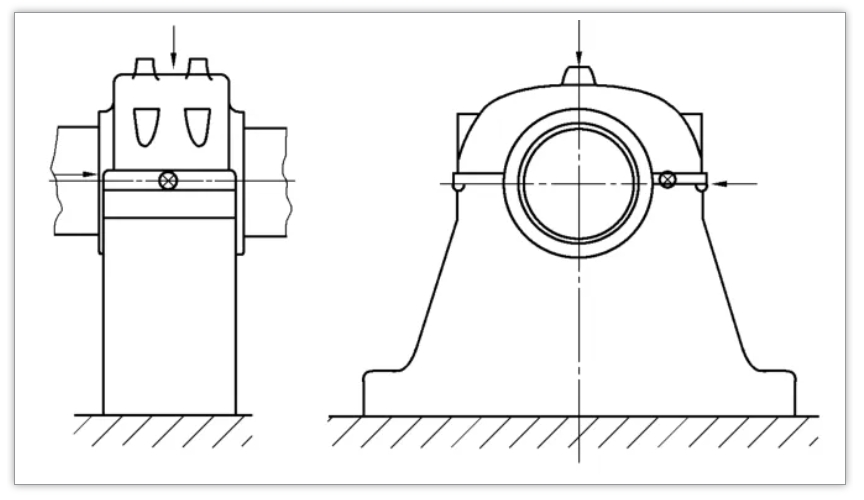

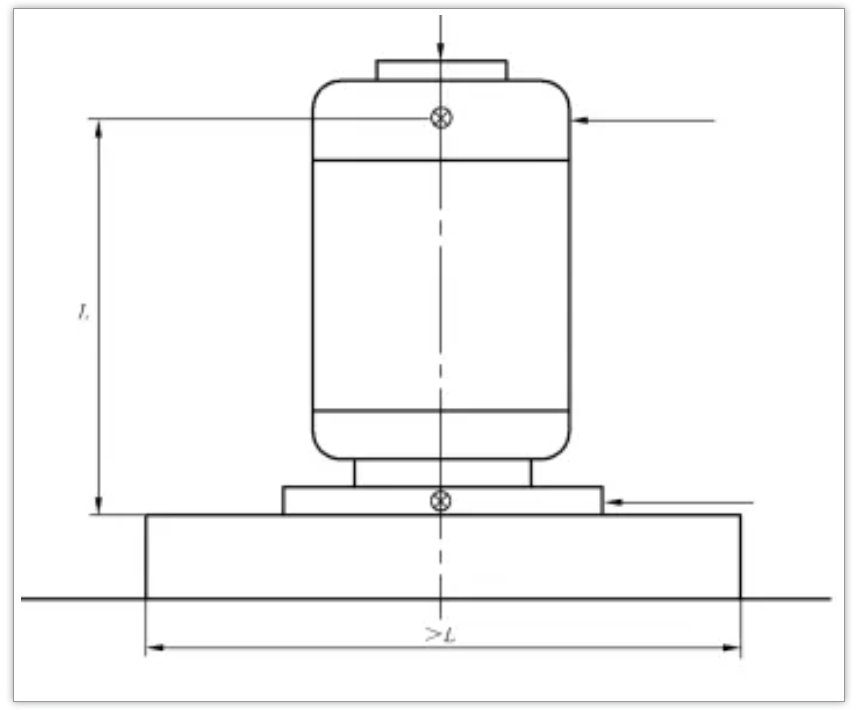

When the motor uses a pedestal bearing structure, its vibration measurement is shown in Figure 3; vertically mounted motors are measured according to Figure 4. In actual operation, if it is impossible to measure according to the above regulations, full communication should be conducted with the actual user of the motor to agree on the conditions for delivery and acceptance.

Figure 3

Figure 4

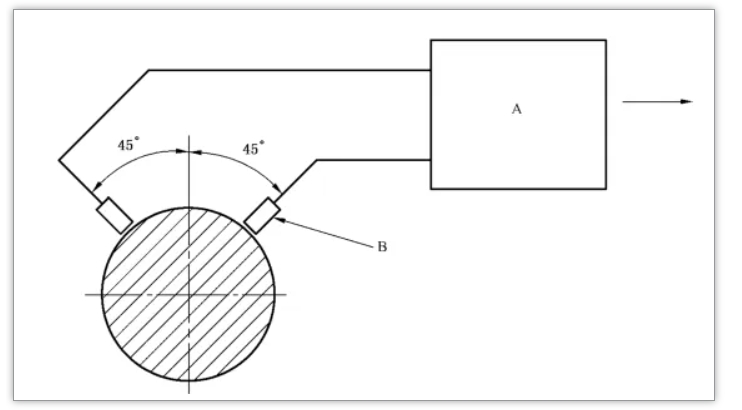

When measuring relative shaft displacement, a non-contact sensor should be installed inside the bearing. If this is not possible, it should be installed near the bearing cap to directly measure the axial relative displacement of the shaft journal. The recommended radial measurement point locations are shown in Figure 5.

Figure 5

For motors requiring dynamic vibration monitoring, dynamic sensors must be installed. The contact between the vibration sensor and the motor surface must comply with the sensor manufacturer's specifications and must not interfere with the vibration state of the motor under test. To this end, the total coupled mass of the sensor assembly should be less than one-fiftieth of the motor's mass.

XINDA

XINDA