Egyptian client visit Xinda Motor plant for E-cargo vehicle motors

On Saturday afternoon, 24th Jan. 2026,I helped with translation at a friend's invitation. The group photo of the five people is: Xiao Kou, the quality control manager, Mr. Mohamed de Lazio, myself, and General Manager Wang. The photographer was Sena. Mr. Mohamed (hereinafter referred to as Mr. Mo) is Egyptian.

The three of us drove to Zibo Station to pick him up. Mr. Mo asked us in Chinese, "Are you from Zibo?" He had no luggage, only a notebook and a pen. After getting in the car, we went to Milan Xidian Restaurant for lunch. Mr. Mo is Arab, so we considered having steak. Because it was full on the weekend, we waited for about twenty minutes. Mr. Mo's schedule was very tight; he had to rush back to the station at 5 pm to return to Shanghai. He is based in Shanghai. While waiting for the steak, we chatted and learned that Mr. Mo is of Arab and Germanic descent, his native languages are Arabic and German, he speaks English, and knows a little Chinese. I was very excited because I have been learning German, so I had the opportunity to speak a few words of German. I said, "Mussen wir langsam warten" (in German, we will have to wait a long time). The steak was finally served. I said in German, "Das gefaellt mir sehr," and Mr. Mo replied, "Sehr gut." The sirloin with bone that I chose was excellent, and I ate it with great relish. Mr. Mo said he really liked China, considering it the most developed country, safe, convenient, and comfortable. He loved China and Chinese culture. I told him that Egypt and China are both ancient civilizations with great cultures. Time was tight, so we quickly finished eating and rushed to the factory.

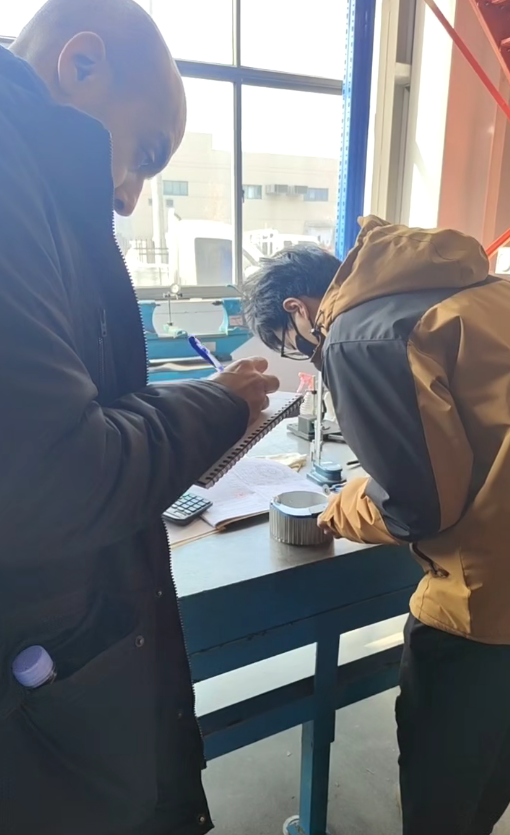

Once there, Mr. Mo started working. He was incredibly meticulous, asking about everything from raw material quality control in the workshop to the end of the production line, laboratory testing, procurement, and after-sales service, requesting demonstrations and presentations. I'd never had such a serious and meticulous client before, and we answered and demonstrated in great detail. I spent the entire afternoon translating, and my throat was parched. Below is the record of workshop visitation:

Xinda Motor plant hall

Motor quality control staff is measuring

Mr. Mohamed asked for all details of how quanlity control is operated, including incoming material and during production processing. We demonstrated each part thanks to our QA manager who helped a lot in the entire visitation. All the incoming material would be checked with 20% sampling, if any defect would be rejected, if good then will be allowed entry into the plant for warehouse zone.

Mr. Mohamed checked our rotors processing of motor production line

then the stator checkpoint

stator processing

At end of motor production line, there is chamber for final inspection over the rpm and motor control, and performance of motors, if any failure of defected would be pull over to the cart for check and repair.

After workshop, we went for the meeting room to talk over the checklist and our purchase section. Mr. Mohamed ordered a motor for his small van, which needed to be suitable for the extremely hot and dry environment of the Egyptian desert. Our motors have a maximum temperature of 150 degrees Celsius, and the motor controller will alarm if it exceeds this temperature. Additionally, the local terrain in Egypt has slopes of approximately 30 degrees, including rugged and damaged sections, which could potentially cause the motor to overload during vehicle operation. Considering these operating conditions and temperature variations, we needed to customize a suitable motor for Mr. Mohamed. Therefore, we provided him with a vehicle information sheet to provide detailed vehicle data, which allowed us to calculate the required motor parameters.

Also, We explained the material procurement process in detail, and Mr. Mohamed asked many questions. He was very satisfied with our approach.

We finally finished around 5 pm, took a group photo in the company lobby, and then I took him to the North Station to catch his train. He expressed his hope that we would meet again and thanked me. After seeing Mr. Mo off, we drove back home in the afterglow of the setting sun.

XINDA

XINDA