![]()

The annual output of motors exceeds 1 billion units, and the penetration rate of BLDC motors is expected to continue to increase?

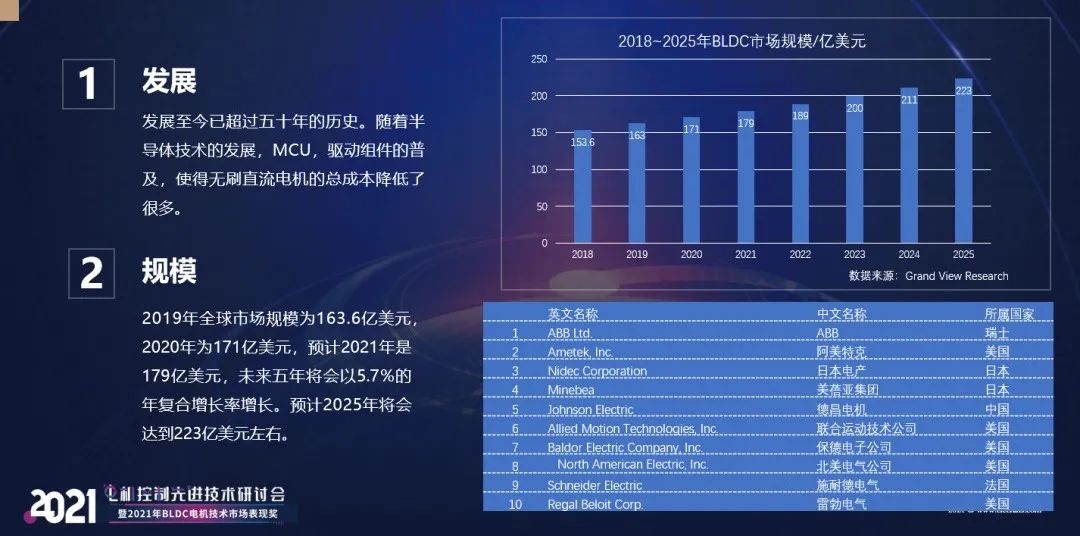

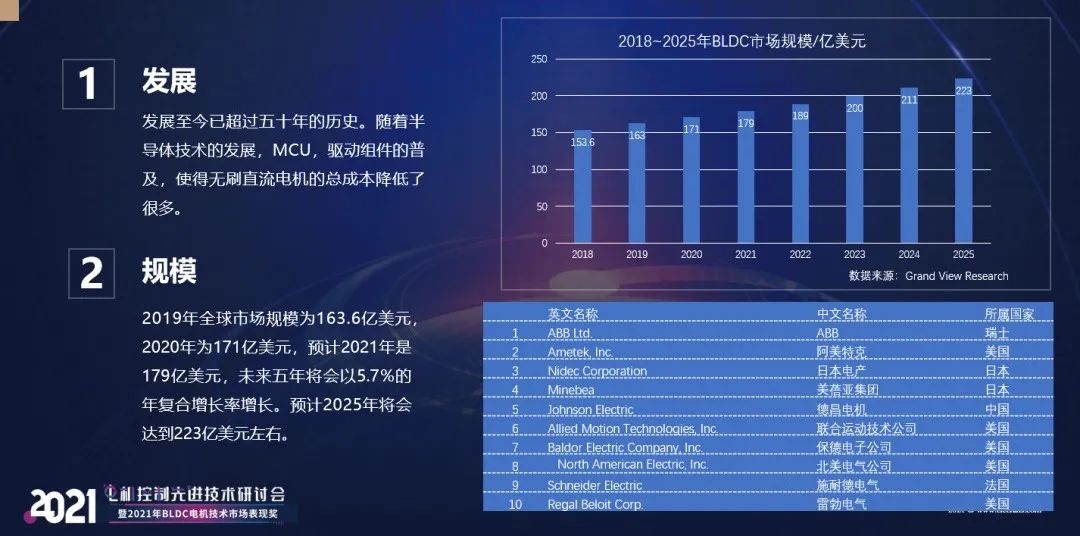

The global motor market has grown considerably with the widespread use of energy-efficient motors in automotive, agricultural, air-conditioning, and washing machine applications. According to the statistics of MarketsandMarkets, the global motor market size in 2019 was 122 billion US dollars. Due to the impact of the new crown epidemic, the market size in 2020 has declined to 113.3 billion US dollars. However, the market has improved this year. Therefore, the agency predicts that the compound annual growth rate of the future motor market will be about 6.9%, and it will reach 169.1 billion US dollars by 2026. In other words, in the future, this will be a large market worth trillions of yuan.

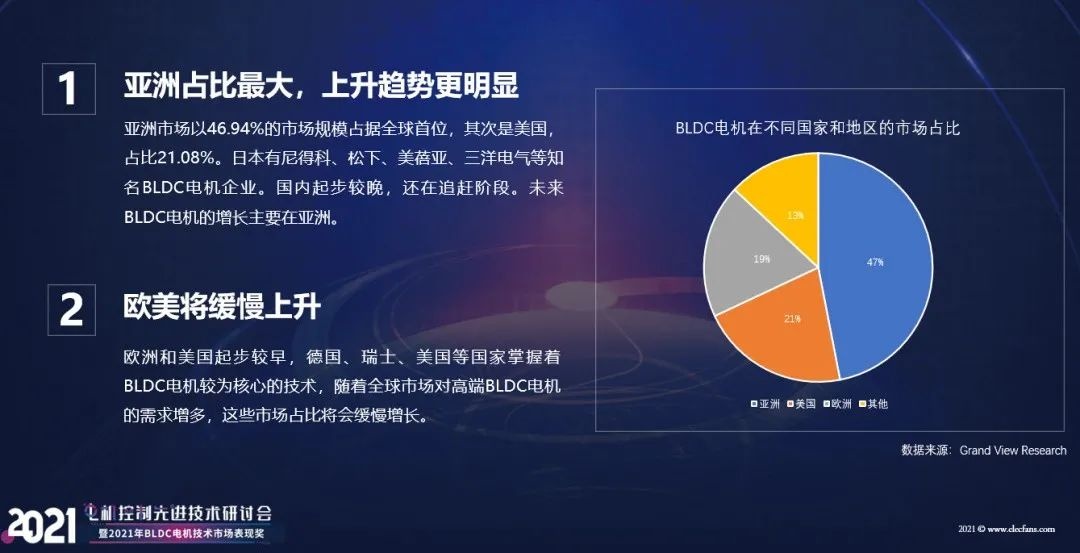

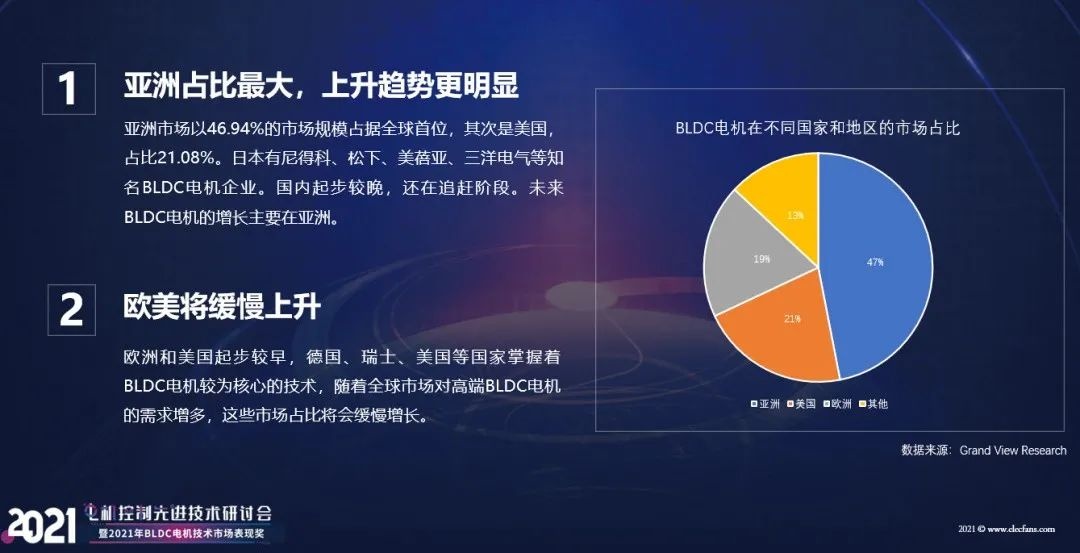

From the perspective of market structure, in the BLDC motor market, the Asian market accounts for the largest proportion, accounting for 46.94%, followed by the United States, accounting for 21.08%. In fact, there are many BLDC motor companies with good technical strength in Asia, but they are mainly concentrated in Japan, such as Nidec, Panasonic, Minebea, and Sanyo Electric. Domestically, it is still mainly in the catching-up stage. But it is foreseeable that the future growth of BLDC motors will mainly come from Asia, and Asia will mainly be in China.

Europe's market share is not small, about 19%. Since Europe and the United States started relatively early, they have mastered many core technologies of BLDC motors. In the future, with the increasing demand for high-end BLDC motors in the global market, the proportion of European and American markets will also grow slowly. But the proportion is definitely not as high as in Asia.

The main application market of the motor

The application of motors is actually very extensive. Most of the moving things need to use motors. Specifically, there are fans, pumps, electric vehicles, power tools, compressors, agricultural machinery, and automotive applications. Specifically, automotive applications account for the largest proportion, accounting for about 40% of the entire motor market. Next, let's take a look at these specific applications.

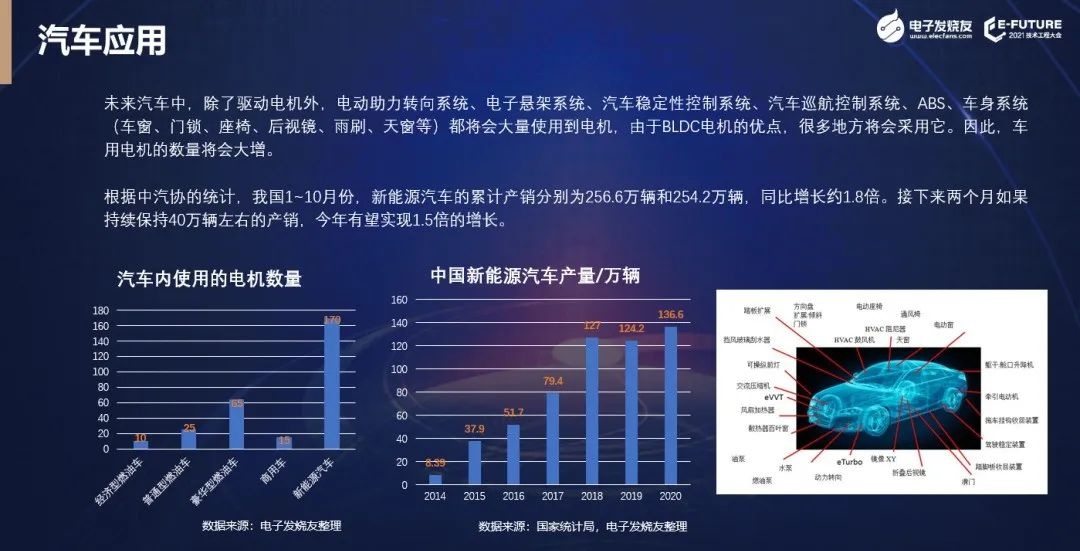

With the rise of new energy vehicles, the penetration of intelligent driving, and the pilot application of the Internet of Vehicles, the trend of electronic vehicles is becoming more and more obvious. In a car, in addition to the drive motor, electric power steering system, electronic suspension system, car stability control system, car cruise control system, ABS, body system (such as windows, door locks, seats, rearview mirrors, wipers, sunroof, etc.) will use a lot of motors.Especially with the development of new energy vehicles, more and more places need to use BLDC motors. Taking the electronic water pump in the car as an example, new energy vehicles need to carry out precise temperature control on the three-electric system. In the case of using water cooling, Each car needs 2~5 electronic water pumps, with an average of 3. The unit price has increased from 100-150 yuan for traditional water pumps to 200-300 yuan.In 2020, China's new energy vehicle electronic water pump market size will be 1.12 billion yuan. In the next few years, from the perspective of the penetration rate of new energy vehicles, in 2020, my country's new energy vehicle production will be 1.366 million units, but by this year, from January to October , The cumulative output of new energy vehicles reached 2.566 million, an increase of about 1.8 times year-on-year. It can be seen that the growth of the electronic automotive water pump market will be very amazing.

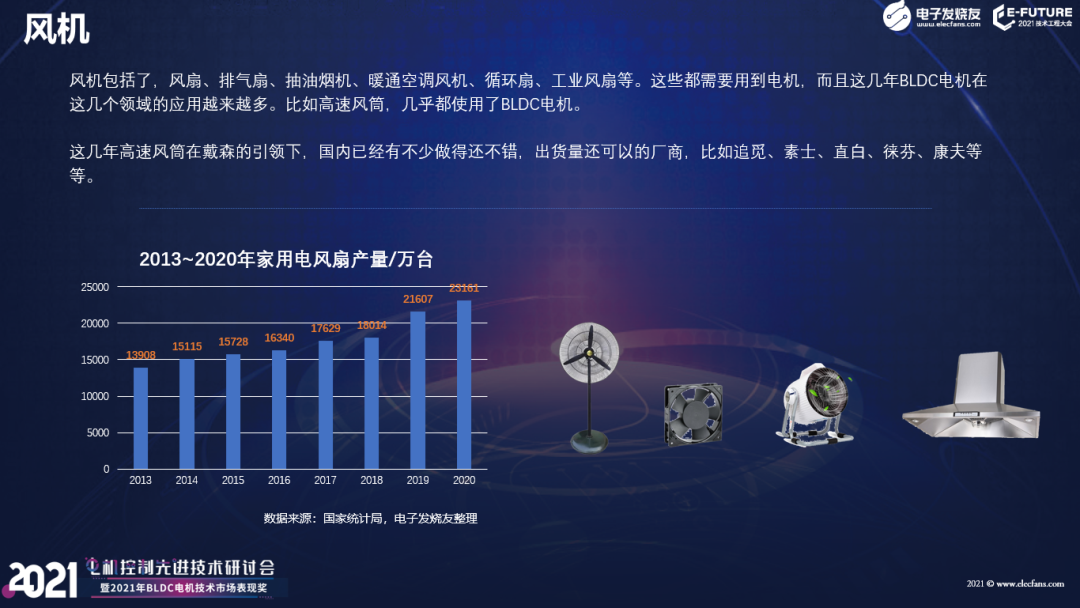

In addition, from the perspective of the number of motors used in the car, generally speaking, economical fuel vehicles will be equipped with about 10 motors, ordinary cars will be equipped with 20 to 30 motors, and luxury cars will be equipped with 60 to 70 motors. Even hundreds of motors, and new energy vehicles will require more motors.In the field of fans, fans include: fans, exhaust fans, range hoods, hair dryers, HVAC fans, circulation fans, industrial fans, etc. The main downstream manufacturers include Midea, Airmate, Gree, Pioneer, Vantage, Boss and so on.From the perspective of household electric fans, the output of household fans in China is very large. According to the data of the National Bureau of Statistics, the number of household electric fans has been increasing year by year from 2013 to 2020, and the output in 2020 is 230 million units.At present, domestic mainstream small home appliance manufacturers, such as Midea, Pioneer, Nicai, Airmate, etc., basically have products using brushless motors on the market. Among them, Emmett has the largest quantity, and Xiaomi has the lowest cost.With the entry of some cross-border manufacturers such as Xiaomi, the conversion rate of brushless motors in the field of household fans has begun to accelerate. Now, in the field of household fans, domestic brushless motor manufacturers already have a place. According to our understanding, in terms of household fans, the penetration rate of BLDC motors is about 15%.In terms of fans, there are range hoods, which are an important part of kitchen appliances. However, due to cost reasons, the brushless conversion rate of range hoods is not high. The current market penetration rate of BLDC is about 10%.There are also many new fans and air purifiers that are also made with brushless motor solutions. At present, the products on the market generally use Nidec external rotor motors for small ones, and EBM fans for large air purifiers. The cost of the brushless motor used here is very close to the cost of the traditional AC motor, so there are many solutions for using brushless motors in fresh air machines.In addition, there is an air circulation fan that has been in production for the past two years. The current value is still high, ranging from 100 to several hundred higher than ordinary fans. There are two or three thousand more expensive ones.There are also some hand-held small fans and portable small ceiling fans that are increasingly using brushless motors. Because the mute effect of the brushless motor is better, the price of the product can be sold higher.In addition, in fact, industrial ceiling fans are not a small market. In the past, large industrial fans were used in factory workshops, which had high power and were not very safe. Industrial fans can be widely used in industrial plants, logistics storage, exhibition halls, gymnasiums, waiting halls, airports and other large places and tall spaces. Industrial ceiling fans using BLDC can meet the national first-level energy consumption standards.Vacuum cleaner applicationVacuum cleaners are also a large market for motor applications. Vacuum cleaners are essential cleaning appliances in European and American households, and their penetration rate is already very high. Therefore, the demand has always been relatively stable. From 2016 to 2020, the sales volume increased from 35.6 million units to 37 million units, with a growth rate of about 5.5%.The volume in China is relatively small. The sales volume in 2016 was only 14 million. By 2020, the sales volume will reach 24.9 million. The compound annual growth rate in the future is expected to be around 15.4%. Growth potential is greater.But in fact, many vacuum cleaners sold in the United States and Europe are made in China. The domestic output of vacuum cleaners is actually very large. For example, more than 80% of the vacuum cleaner products of ODM manufacturers such as Xinbao, Fujia, and Dechang are exported overseas. up.In fact, in recent years, in addition to dust cleaners, there has been a rise in the past few years of a washing machine product that can vacuum, mop, and sweep the floor. Sales are also good. Some related products on online shopping malls have more than 100,000 reviews. These products commonly use brushless motor solutions.Figure: Washing machine productsPower tools are one of the most widely used hardware and electrical products. Because of its light structure, easy to carry and use, high production efficiency, low energy consumption, etc., it is widely used in drilling, cutting, grinding and other processing in various application industries such as construction, decoration, wood processing, metal processing, and other manufacturing industries. links.

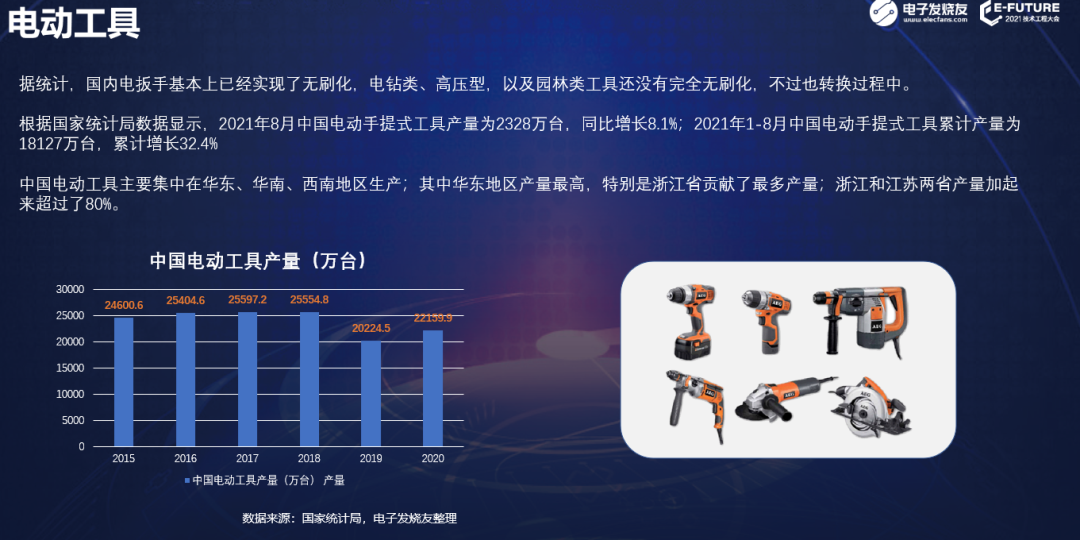

With the continuous development of technology and the gradual acceptance of the concept of DIY, the application range of electric tools is also expanding. Many traditional manual tool operations are more and more replaced by electric tools, and electric tools are also expanding from industrial applications. into family life. The demand for power tools is increasing year by year.The brushless use of electric tools actually started very early. In 2010, some foreign brands launched electric tools with brushless motors. With the maturity of lithium battery technology, the price is becoming more and more affordable, and the magnitude of handheld tools is increasing year by year, and now it can be evenly compared with plug-in tools.In fact, the domestic output of power tools has always been relatively large, and has declined in recent years. According to the statistics of the National Bureau of Statistics, in 2021, the output of electric tools in my country will be about 220 million units. As far as we know, domestic electric wrenches have basically achieved brushless, and electric drills, high-voltage types, and garden tools have not yet been completely brushless, but they are still in the process of conversion. The reason for the slow conversion is mainly due to cost issues. At present, BLDC motors are relatively expensive compared with traditional motors.At present, domestic power tools are mainly produced in East China, South China, and Southwest China; among them, East China has the highest output, especially Zhejiang Province, which contributes the most output; the combined output of Zhejiang and Jiangsu provinces exceeds 80%.

In China, electric bicycles are also a big market. According to the data of the National Bureau of Statistics, in 2020, the output of electric bicycles in my country will reach 29.661 million.The domestic demand for electric bicycles is large. With the implementation of the new national standard, the previous stock market will also need to be replaced with electric bicycles of the new national standard. As far as we know, this stock exceeds 100 million. Think about it, the market is quite big.

Penetration rate of BLDC motors in home appliance market

We also counted the penetration rate of BLDC motors in the field of home appliances. This is more obtained after we exchanged with some people in the industry who are more familiar with the market. It is not necessarily accurate, but it is just a reference for everyone.In fact, the amount of motors used in household appliances is very large. We made a rough statistic, and without counting large appliances such as air conditioners, refrigerators, and washing machines, the annual demand for motors exceeds 800 million units. If counted, it should far exceed the consumption of 1 billion motors.The penetration rate of these markets is generally below 10%. Imagine the future, not to mention new product markets, even if these existing markets are replaced to 50%, or 60%, the market size is quite considerable.The brushless DC motor (BLDC) overcomes the congenital defects of the brushed DC motor and replaces the mechanical commutator with an electronic commutator. Therefore, the brushless DC motor not only has the characteristics of good speed regulation performance of the DC motor, but also has the characteristics of AC The motor has the advantages of simple structure, no commutation spark, reliable operation and easy maintenance. The essence of the brushless DC motor is a DC power input, using an electronic inverter to convert DC to AC, and a three-phase AC permanent magnet synchronous motor with rotor position feedback. Compared with the general traditional DC motor in performance, it has great advantages, and it is the most ideal speed-regulating motor today.

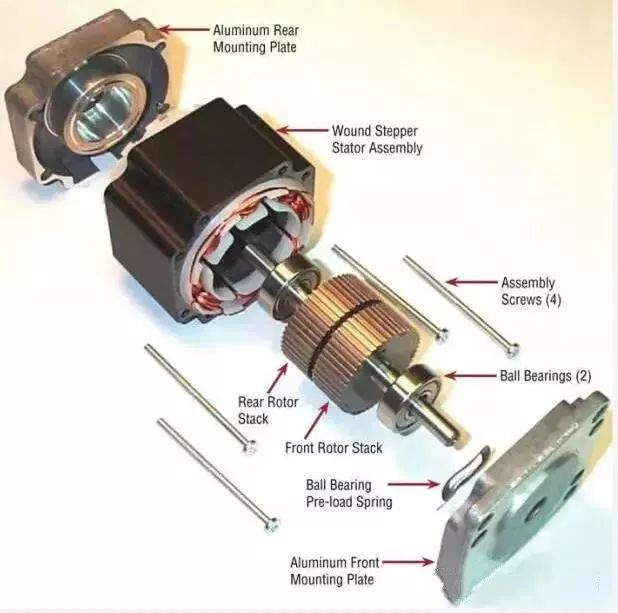

1. Brief introduction of brushed DC motorBefore introducing the brushless DC motor, let's take a look at the brushed motor:DC motors are famous for their good starting performance and speed regulation performance. Among them, brushed DC motors, which belong to the category of DC motors, use mechanical commutators to make the driving method simple. The schematic diagram of its model is shown in the figure below.Schematic diagram of DC motor (brush motor) operationThe motor is mainly composed of a stator made of permanent magnet materials, a rotor (armature) with coil windings, a commutator and brushes. As long as a certain DC current is passed through the A and B ends of the brush, the commutator of the motor will automatically change the magnetic field direction of the motor rotor, so that the rotor of the DC motor will continue to run.DC motors have the following disadvantages

The structure is relatively complicated, which increases the manufacturing cost;It is easily affected by the environment (such as dust, etc.), which reduces the reliability of work;Sparks will be generated when reversing, which limits the scope of use;Easy to damage, increased maintenance costs, etc.

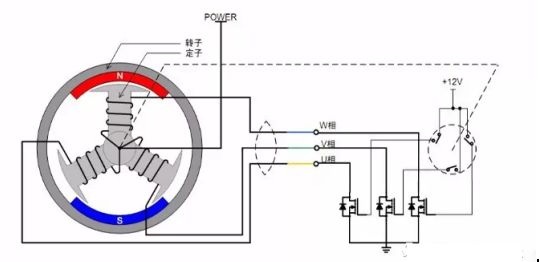

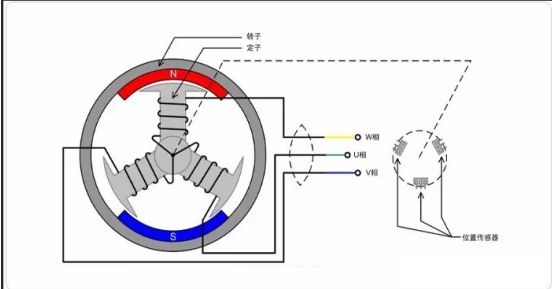

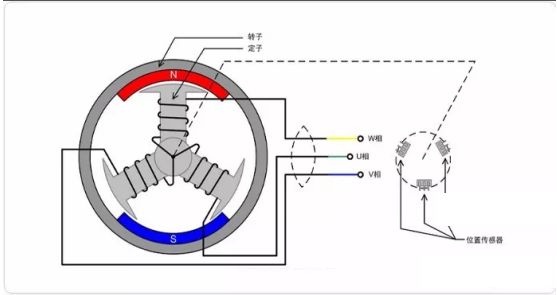

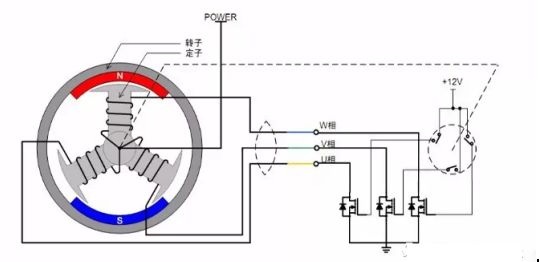

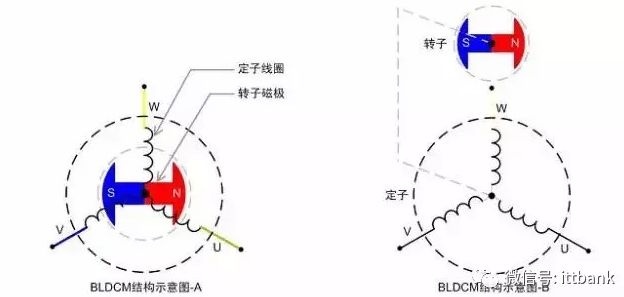

2. Brief introduction of brushless DC motorThe "BL" in the BLDC motor means "brushless", that is, the "brush" in the DC motor (brush motor) is gone.The brushless DC motor (BLDC) replaces the mechanical commutator with an electronic commutator, so the brushless DC motor not only has the characteristics of good speed regulation performance of the DC motor, but also has the characteristics of the simple structure of the AC motor, no commutation sparks, and reliable operation. and easy maintenance.Figure 1: Schematic diagram of a brushless DC motor modelSchematic diagram of the operation of a BLDC motorThe brushless DC motor mainly consists of a rotor made of permanent magnet material, a stator with coil windings and a position sensor (optional). It can be seen that it has a lot in common with the DC motor, the structure of the stator and the rotor is similar (the original stator becomes the rotor, and the rotor becomes the stator), and the wiring of the winding is basically the same. However, structurally they have an obvious difference: BLDC motors do not have the commutator and brushes in DC motors, but position sensors instead. In this way, the structure of the motor is relatively simple, which reduces the manufacturing and maintenance costs of the motor, but the brushless DC motor cannot automatically commutate (phase), and the price of sacrifice is the increase in the cost of the motor controller (such as the same three-phase DC motor, there are The driving bridge of the brush DC motor needs 4 power tubes, and the driving bridge of the brushless DC motor needs 6 power tubes).Figure 1 shows one of the low-power three-phase, star-connected, single-pair magnetic pole-to-pole brushless DC motors. Its stator is inside and the rotor is outside. The structure of another brushless DC motor is just the opposite of this one. Its stator is outside and the rotor is inside, that is, the stator is a frame composed of coil windings, and the rotor is made of permanent magnet materials.Brushless DC motors have the following characteristics

The brushless DC motor has good external characteristics and can output large torque at low speed, so that it can provide large starting torque;The brushless DC motor has a wide speed range and can run at full power at any speed;The brushless DC motor has high efficiency and strong overload capacity, which makes it have excellent performance in the drag system;

The regenerative braking effect of the brushless DC motor is good, because its rotor is made of permanent magnet material, the motor can enter the generator state when braking;The brushless DC motor is small in size and high in power density;The brushless DC motor has no mechanical commutator, and adopts a fully enclosed structure, which can prevent dust from entering the motor, and has high reliability;Brushless DC motors are simpler to drive and control than asynchronous motors.

3. Working principle of brushless DC motorThe stator of a BLDC motor is the coil-wound armature and the rotor is the permanent magnet. If only a fixed DC current is passed to the motor, the motor can only generate a constant magnetic field, and the motor cannot rotate. Only the position of the motor rotor can be detected in real time, and then the corresponding current is supplied to the different phases of the motor according to the position of the rotor, so that The stator generates a rotating magnetic field whose direction changes uniformly, and the motor can rotate with the magnetic field.Figure 2 is a schematic diagram of the rotation principle of the brushless DC motor. For the convenience of description, the center tap of the coil of the motor stator is connected to the motor power supply, and the terminals of each phase are connected to the power tube. When the position sensor is turned on, the G pole of the power tube is connected to the power tube. 12V, the power tube is turned on, and the corresponding phase coil is energized. As the three position sensors turn on with the rotation of the rotor, the corresponding phase coils are also energized in turn, so that the direction of the magnetic field generated by the stator is constantly changing, and the rotor of the motor also rotates. This is the brushless DC motor. Basic rotation principle - detect the position of the rotor, energize each phase in turn, so that the direction of the magnetic field generated by the stator changes continuously and evenly.

Figure 2: Schematic diagram of brushless DC motor rotation principleIn order to facilitate understanding, the following content of this article uses these two symbols as shown in the figure below as a model introduction. Figure A shows that the rotor and stator of the motor are on the same center, and Figure B is on a different center. This is for the convenience of explaining the internal magnetic field of the motor.Schematic diagram of brushless DC motor structureThe stator windings of the motor are mostly made into a three-phase symmetrical star connection, which is very similar to the three-phase asynchronous motor. Magnetized permanent magnets are attached to the rotor of the motor. In order to detect the polarity of the motor rotor, a position sensor is installed in the motor. The driver is composed of power electronic devices and integrated circuits, etc. Its functions are: to receive the start, stop, and brake signals of the motor to control the start, stop, and brake of the motor; to accept the signal of the position sensor and the forward and reverse signals to control the reverse The on-off of each power tube of the variable bridge generates continuous torque; receives speed command and speed feedback signal to control and adjust the speed; provides protection and display, etc.DC motors have fast response, large starting torque, and the ability to provide rated torque from zero speed to rated speed, but the advantages of DC motors are also its disadvantages, because DC motors must produce constant rotation under rated load. Torque performance, the armature magnetic field and the rotor magnetic field must maintain a constant 90°, which requires the use of carbon brushes and commutators. Carbon brushes and commutators will generate sparks and carbon powder when the motor is rotating. Therefore, in addition to causing damage to components, the application occasions are also limited. AC motors have no carbon brushes and commutators, are maintenance-free, sturdy, and widely used, but in terms of characteristics, if they want to achieve the performance equivalent to DC motors, complex control technology must be used to achieve them. Nowadays, with the rapid development of semiconductors, the switching frequency of power components is much faster, which improves the performance of the drive motor. The speed of the microprocessor is also getting faster and faster, which can realize the control of the AC motor in a rotating two-axis Cartesian coordinate system, and properly control the current components of the AC motor on the two axes to achieve control similar to that of the DC motor and have the same performance as the DC motor. performance.In addition, many microprocessors have integrated the functions necessary to control the motor into the chip, and the volume is getting smaller and smaller; like analog-to-digital converter (adc), pulse width modulation (pulse wide modulator, pwm)...etc. The brushless DC motor is an application that electronically controls the commutation of the AC motor to obtain characteristics similar to the DC motor without the lack of the DC motor mechanism.4. Driving method of brushless DC motorThe driving methods of brushless direct motors can be divided into various driving methods according to different categories, each of which has its own characteristics.1. According to the driving waveform: square wave driving, this driving method is convenient to realize, and it is easy to realize the motor without position sensor control;2. Sinusoidal drive: This drive method can improve the operation effect of the motor and make the output torque uniform, but the implementation process is relatively complicated. At the same time, this method has two methods: SPWM and SVPWM (space vector PWM). The effect of SVPWM is better than that of SPWM.5. Application field of brushless DC motorApplication field 1, office computer peripheral equipment, electronic digital consumer goods field.This is the field with the widest popularity and largest number of brushless DC motors. For example, printers, fax machines, copiers, hard disk drives, floppy disk drives, movie cameras, tape recorders, etc., which are common in daily life, all have brushless DC motors in the driving control of their main shafts and auxiliary movements.Application field two, industrial control field.In recent years, due to the large-scale research and development of brushless DC motors and the gradual maturity of technology, the distribution range of its drive system in industrial production has also expanded, and it has gradually become the mainstream of industrial motor development. The research and attempts to reduce production costs and improve operating efficiency have achieved remarkable benefits. Major manufacturers also provide different types of motors to meet the needs of different drive systems. At this stage, brushless DC motors are involved in industrial production such as textiles, metallurgy, printing, automated production lines, and CNC machine tools.The third application field is the field of medical equipment.In foreign countries, the use of brushless DC motors has become more common, and can be used to drive small blood pumps in artificial hearts; Both use brushless DC motors.The fourth application area is the automotive field.According to analysis on the market, general family cars need 20-30 permanent magnet motors, while each luxury car needs as many as 59. There are motors in every part. As the automobile industry develops in the direction of energy conservation and environmental protection, the motors used must also meet the standards of high efficiency and low energy consumption. The advantages of brushless DC motors such as low noise, long life, no spark interference, and convenient centralized control are fully in line. With the increasing maturity of its speed regulation technology, the cost performance will become higher and higher. application will be more extensive.Application field five, the field of household appliances."Frequency conversion" technology has become very common. As a symbol of Chinese home appliances, it has gradually occupied most of the consumer market. "DC frequency conversion" is favored by manufacturers, and there is a trend of gradually replacing "AC frequency conversion". This transformation is essentially the transition of the electric motors used in household appliances from induction motors to brushless DC motors and their controllers, in order to meet the requirements of energy saving, environmental protection, low noise intelligence, and high comfort. The development direction of brushless DC motor is the same as that of power electronics, sensors, control theory and other technologies. It is the product of the combination of various technologies, and its development depends on the innovation and progress of each technology related to it.

XINDA

XINDA