![]()

Do you know the nine advantages and three disadvantages of switched reluctance motors? A comprehensive analysis of the application fields of switched reluctance motors

In recent years, switched reluctance motors have gradually entered the market. Because this motor has advantages that other motors do not have, it has gradually become the main direction of future market development. At present, it has been successfully used in electric vehicle drives, general industries, household appliances and Textile machinery and other fields. So what exactly are the advantages of switched reluctance motors? Let's find out together!

The switched reluctance motor speed control system is a mechatronics product based on modern power electronics and microcomputer control technology. It is composed of switched reluctance motor and microcomputer intelligent controller. It is characterized by high efficiency, good energy saving effect, wide range of speed regulation, no impact starting current, large starting torque and flexible control. In 1998, my country included the development of motor speed regulation energy saving and power electronic power saving technology into the "Energy Conservation Law of the People's Republic of China". kWh/year. Therefore, this kind of motor is widely used in transport vehicle drive, planer, forging equipment and other occasions that require heavy-duty starting, frequent starting, forward and reverse rotation.

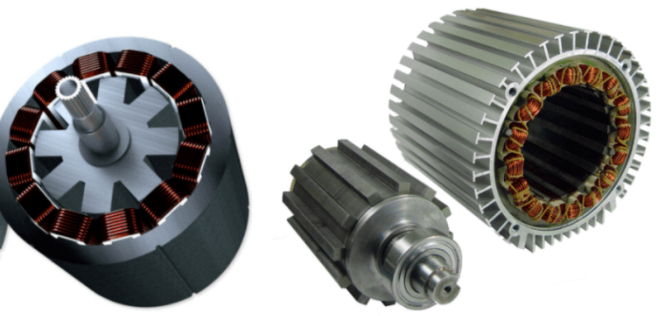

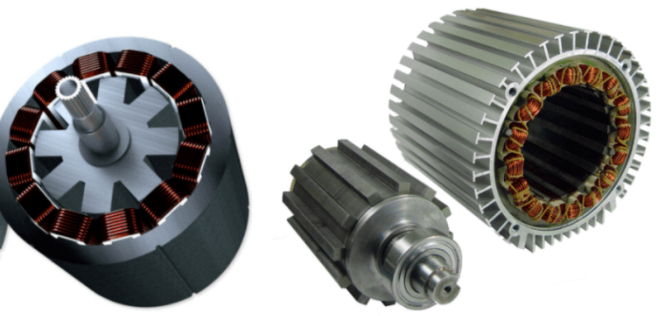

In recent years, with the gradual deepening of the concept of motor energy saving, switched reluctance motors are being used in various occasions due to the following characteristics. Features of the switched reluctance motor speed control system:1. High efficiency and good energy saving effect. After testing, its overall efficiency is at least 3% higher than that of AC asynchronous motor frequency conversion speed regulation system, and it can be increased by at least 10% at low speed. Compared with DC speed regulation, cascade speed regulation, electromagnetic speed regulation, etc., the power saving effect is more obvious.2. Large starting torque, suitable for heavy-load starting and occasions with obvious load changes and frequent starting. The test found that when the starting torque reaches 150% of the rated torque, the starting current is only 30% of the rated current, the advantage is very obvious3. Wide range of speed regulation. The switched reluctance motor can run at low speed for a long time. Due to its high efficiency, the temperature rise at low speed is lower than that under the rated working condition. Rotating speed.4. It can be started and stopped frequently in forward and reverse directions. The system has good controllability, good braking performance, regenerative braking can be realized, and the power saving effect is remarkable.5. The starting current is small to avoid the impact on the power grid. Switched reluctance motors have soft start characteristics, and there is no phenomenon that the starting current of ordinary AC motors is greater than 5-7 times the rated current.Sixth, the power factor is high, no need to add reactive power compensation device, the test found that the power factor of the switched reluctance motor system is greater than 0.98 at no-load and full-load.7. The structure of the motor is simple and strong, the manufacturing process is simple, the cost is low, and the work is reliable, and it can be applied to various harsh high-temperature and strong-vibration environments.8. It can still work when there is a phase loss or overload. When there is a phase loss in the power supply, or any phase of the motor or controller fails, the output power of the motor is reduced, but it can still run. When the system exceeds the load by more than 120%, the speed will only drop, without burning the motor and control cabinet.9. The power converter in the controller is connected in series with the motor winding, so there will be no through failure that may occur in the power converter of the frequency conversion speed regulation system, and the reliability is greatly improved.The current motors have both advantages and disadvantages, and no motor can replace all other types of motors. Switched reluctance motors also have the following disadvantages:1. Torque ripple: The switched reluctance motor works in the pulse power supply mode, the instantaneous torque ripple is large, and when the speed is very low, the stepping state is obvious, and due to its own nonlinearity, torque control is difficult. Although there are many articles on SRD direct torque control technology, it is still difficult to achieve precise torque control. In precision control applications such as servo, SRD has no advantages compared with other types of motors.2. Noise: The phase windings of the switched reluctance motor are turned on in turn, and the radial force causes the stator to deform, which is more obvious when commutating. The motor is noisy. Reducing vibration and noise is an important research topic. The method of speed regulation and the structure of the motor have been studied and improved, but compared with other motors, the noise is still relatively large.3. Position detector: The position detector makes the switched reluctance motor with simple structure inferior and reduces the reliability of the system. Therefore, it is necessary to explore a practical detection scheme without a position detector. At present, most studies at home and abroad are to use the transient inductance information of the stator winding to realize the non-position detector scheme, but the practical application still needs further research.The application markets of domestic switched reluctance motors mainly include:(1) Forging machinery: At present, this is one of the most successful applications of switched reluctance motors. This time it fully meets the above five conditions. It has the advantages of overload requirements, positive and negative rotation, wide speed range, energy saving, etc., and completely ignores the shortcomings of switched reluctance motors: noise, vibration and torque ripple. In the switched reluctance motor business world, there is a saying that forging gets the world. Shandong Kehui Company has been in a leading position in the country in recent years, which is inseparable from its early and accurate market development and positioning. Figure 2 forging machinery (2) Textile machinery: First of all, we should thank foreigners for their applications. China's mainstream imported textile machinery Picanol took the lead in adopting switched reluctance motors, which made domestic loom manufacturers naturally recognize switched reluctance motors. Since 2009, switched reluctance motors have gradually found a place on rapier and towel looms. Textile applications meet the conditions of 1, 3 and 5 above, energy saving, fast start-up (the motor can reach the rated speed from zero speed through 3 rotations), and no vibration and noise requirements. The switched reluctance motor used in foreign looms is a four-phase 8/6-pole motor, while the early use of our country is a three-phase 12/8-pole motor. At present, my country has also introduced four-phase motors, which may gradually eliminate the three-phase 12/8 structure in the textile industry. Strangely, Beijing Chinatex was born in the Textile Research Institute. However, Beijing Chinatex's switched reluctance motor has never been promoted on textile machinery. On the contrary, Shandong, Shenzhen, Hangzhou and other companies have been better promoted in the textile industry.

Figure 3 textile machinery(3) Oilfields and coal mines: Energy and environmental protection have always been the focus of the national strategic layout. After using switched reluctance motors in pumping units, coal mine conveyor belts and other occasions, the effect is still obvious. In recent years, Shengli Oilfield, Zhongyuan Oilfield and Changqing Oilfield have all carried out transformation projects, which generally meet the transformation requirements, but the oilfield market is the position of state-owned enterprises. You know, it is difficult to achieve large-scale promotion at present. As for coal mines, it is difficult to succeed or fail for Beijing Zhongfang. These years are the off-season for coal, and it is difficult to scale up.Figure 4 Oilfield pumping unit (4) Small household appliances: This aspect mainly focuses on the application of high-speed switched reluctance motors. Foreign vacuum cleaners, cooking machines, wall breaking machines and washing machines use switched reluctance motors in large quantities, with significantly improved performance, large quantities and wide ranges. However, in this regard, there are only a few domestic news that mention the development of prototypes, and large-scale applications have not yet been seen. Perhaps the cost price is the main bottleneck restricting the promotion of these occasions.(5) Electric vehicles: For switched reluctance motors, it can be a pain to mention electric vehicle applications. Whether at home or abroad, the earliest prototypes of switched reluctance motors were developed for electric vehicles. They are optimistic about the advantages of large starting torque and good acceleration performance of switched reluctance motors, which are very suitable for the application of electric vehicles. Huazhong University of Science and Technology and Beijing China Textile Co., Ltd. jointly installed 20 switched reluctance motors for hybrid buses in Wuhan, and conducted long-term operation tests, and achieved good results. However, due to noise and power density issues, the electric vehicle market has been basically occupied by permanent magnet motors in recent years, which is also related to the low price of permanent magnet motors in China. In the long run, permanent magnets are non-renewable resources and cannot meet the huge market demand of electric vehicles. SRM practitioners should continue to dig deeper and wait for the flowers to bloom.

Figure 6 SRD driven mining forklift (6) Other occasions: In recent years, the number of enterprises producing switched reluctance motors has gradually increased, and enterprises have also gone overseas to display their talents. They have tried it on different occasions. The simplest energy-saving transformation occasions, such as fans, water pumps, etc., as well as ball mills, sliding doors, shears, starters/generators, injection molding machines, etc., have also achieved certain results, but the scale of use in these occasions is still small . It remains to be seen whether it can be promoted across the industry in the future.Conclusion: The switched reluctance motor is a new type of speed control system developed in the past 30 years. Its advantages and disadvantages are also obvious. In order to attract investment, it is unrealistic for individual manufacturers to try to replace ordinary asynchronous motors (or innovative plans) with switched reluctance motors. How to combine the characteristics of field application, give full play to the advantages of switched reluctance motors, avoid or reduce the disadvantages caused by its shortcomings, is the direction that researchers should continue to work hard!

XINDA

XINDA