Introduction to the application of various types of motors

Introduction to the application of various types of motors

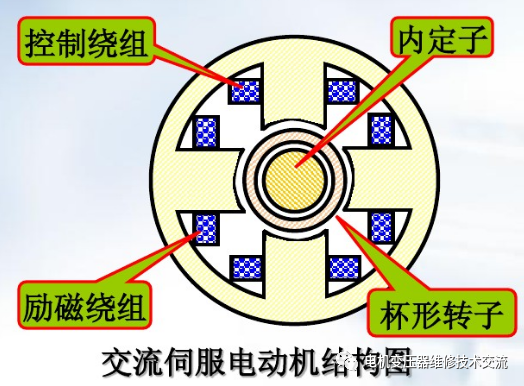

1. Servo motor: Widely used in various control systems, it can convert the input voltage signal into the mechanical output on the motor shaft, and drag the controlled component to achieve the purpose of control.

2. Stepper motor: It is mainly used in the field of CNC machine tool manufacturing. Since the stepper motor does not require A/D conversion and can directly convert digital pulse signals into angular displacement, it has always been considered the most ideal CNC machine tool actuator. It can also be used in other machinery, such as a motor in an automatic feeder, and can be used in printers and plotters.

3. Torque motor: Torque motor is a special motor with soft mechanical characteristics and wide speed regulation range. The shaft of this motor does not output power with constant power but with constant torque. Torque motors include: DC torque motors, AC torque motors, and brushless DC torque motors. In industries such as machinery manufacturing, textile, paper, rubber, plastic, metal wire and wire and cable, products need to be wound on rolls (discs). The diameter of the winding is bigger and bigger from the beginning to the end. In order to keep the tension of the rolled object uniform (that is, the line speed remains constant), the reel speed is required to be smaller and the winding force is larger .

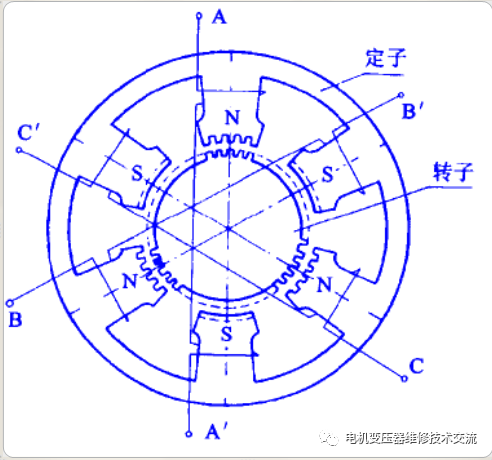

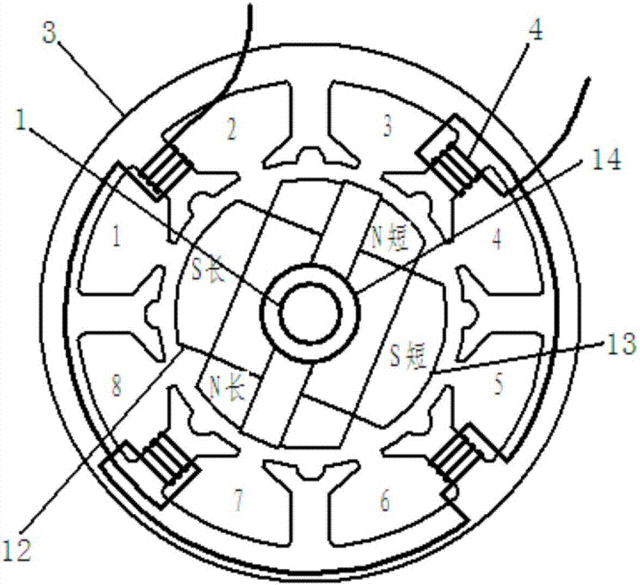

4. Switched reluctance motor: Switched reluctance motor is a new type of speed-regulating motor. The switched reluctance motor (SRM) used in the speed-regulating system is the component that realizes electromechanical energy conversion in SRD, and it is also the difference between SRD and other motor drive systems. main sign. SRM series double salient pole variable reluctance motor, the salient poles of the stator and rotor are laminated by ordinary silicon steel sheets. The rotor has neither windings nor permanent magnets. There are concentrated windings on the stator poles. The two radially opposite windings are connected together, which is called "one phase". The SR motor can be designed into a variety of different phase structures, and the stator and rotor There are many different combinations of poles.

5. Brushless DC motor: good linearity in mechanical characteristics and adjustment characteristics, wide range of speed regulation, long life, easy maintenance, low noise, and no series of problems caused by brushes, so this kind of motor is used in the control system There are great applications.

6. DC motor: It has the advantages of good speed regulation performance, easy starting, and the ability to start with a load. Therefore, the application of DC motors is still very wide, especially after the emergence of thyristor DC power supplies.

7. Asynchronous motor: It has the advantages of simple structure, convenient manufacture, use and maintenance, reliable operation, small mass and low cost. Asynchronous motors are mainly used to drive most industrial and agricultural production machinery such as machine tools, water pumps, blowers, compressors, hoisting equipment, mining machinery, light industrial machinery, agricultural and sideline product processing machinery, household appliances and medical equipment. It is widely used in household appliances, such as electric fans, refrigerators, air conditioners, vacuum cleaners, etc.

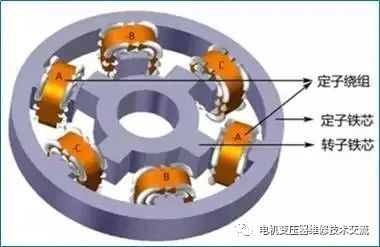

8. Synchronous motors: mainly used for large machinery, such as blowers, water pumps, ball mills, compressors, rolling mills, and small and micro instruments or as control components. Among them, the three-phase synchronous motor is its main body. In addition, it can also be used as a condenser to deliver inductive or capacitive reactive power to the grid.

XINDA

XINDA