Comparison of advantages and disadvantages of using aluminum shell for motor

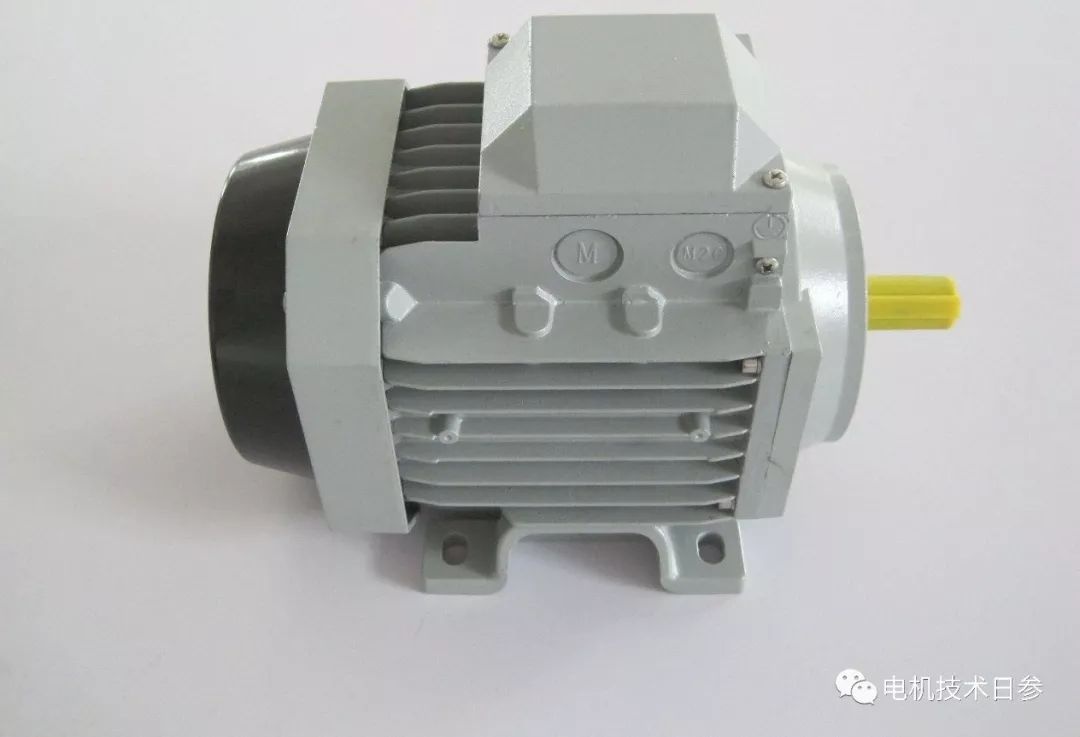

The metal shell of the motor is mainly made of cast iron, steel plate and aluminum. With the pursuit of the appearance and beauty of the motor, the aluminum shell motor is continuously recognized by the market, but as a motorist, we are very clear about the difference between the aluminum shell motor and the cast iron shell. We should evaluate the motor performance, cost, compliance with working conditions, market acceptance and other aspects.

Motors with a center height of 80 to 200 have both cast iron shells and aluminum shells; motors with a center height of 315 or more have almost no aluminum shells, mainly because the mechanical strength is relatively poor. But the two materials do not have much influence on other performances of the motor. Ms. participated in the basic classification of the difference between the two to share with you.

(1) The density of aluminum is relatively small, which can reduce the weight of the whole machine. For small-sized motors, the aluminum casing is preferred based on the strength compliance. The overall price of the two is basically the same, but the appearance of the aluminum casing motor is better.

(2) The cast iron shell is durable, can withstand beating, and has high mechanical strength; compared with the aluminum shell, it is softer and easily forms scars on the surface.

(3) Iron-cased motors are prone to rust, especially in hot flashes; but aluminum-cased motors have poor corrosion resistance.

(4) The heat dissipation coefficient of aluminum is much better than that of cast iron, and the heat dissipation of iron is worse than that of aluminum.

The mechanical function of pure aluminum itself is not high, but its light weight and casting fluidity are unmatched by other metals, and the aluminum element is relatively active and can be combined with other metals to form an aluminum alloy. With admiration, some high-tech equipment takes advantage of this, such as airplanes and other equipment. In fact, most of the aluminum we see is aluminum alloy.

The characteristic of cast iron is that the manufacturing process is very mature, the threshold of entry is low, and the cost is low, but its own defect is only iron-carbon alloy, and compared with aluminum, cast iron is not easy to combine with other metals, which is inherently determined by its own characteristics of.

Aluminum is an active metal, and a dense oxide film with a thickness of about 50 angstroms (1 angstrom = 0.1 nanometers) is formed immediately on the surface of aluminum in dry air, so that aluminum will not be further oxidized and can withstand water; but aluminum powder is easily mixed with air Combustion; molten aluminum can react violently with water; aluminum is amphoteric, easily soluble in strong alkali, and also soluble in dilute acid. This is a problem that must be considered when choosing an aluminum shell base.

XINDA

XINDA