Flat wire motor equipment market "soul 5 consecutive questions"?

The production of drive motors requires a large amount of special equipment. With the increase in labor costs and motor performance requirements, intelligent production will gradually replace traditional production equipment and become a future trend; with the rapid development of new energy vehicles and intensified competition in the industry, domestic production equipment will replace imports The equipment process is accelerated, and the market prospect of domestic motor production equipment is good, with large profit margins.

1 Q: What is the market situation of motor production line equipment?

The technological progress of the motor production line equipment directly drives the overall transformation of the flat wire. Although flat wire motors have been accumulated a long time ago, their application in new energy drive motors has not been promoted in the past, and there is a lack of successful experience. Compared with round wire motors, flat wire motors rely more on automated production lines to achieve high-efficiency and mass production. Due to the immaturity of various technologies, the product yield rate is not high and the production efficiency is low. Market suppliers have limited experience and production capacity, which is not conducive to the practical application of flat wire motors at the technical and market levels. Nowadays, many domestic enterprises have completed the assembly, commissioning and operation of multiple trial production lines and mass production lines, and their feasibility has been verified.

Production line equipment suppliers mainly provide motor manufacturers with the design, manufacture and commissioning of intelligent production lines and equipment, which is an asset-light model with large profit margins. Such manufacturers generally provide a complete set of turnkey projects of planning, R&D, design, assembly, commissioning, and service. The business model is mainly divided into two types: whole-line assembly and stand-alone equipment sales. The former has a higher single value, and the average value of a production line is Between tens of millions and more than 100 million yuan, the gross profit can reach about 40%. This is due to the high technical threshold of flat wire motors and the higher precision automation equipment, so the investment in production lines is larger than that of traditional round wires, and equipment suppliers can enjoy higher profit margins. If we compare the equipment manufacturer with the motor manufacturer, we can find that the high investment of the motor manufacturer in the production line is transferred to the equipment manufacturer, which becomes high value. Moreover, equipment manufacturers only need to purchase parts for assembly of production lines, which is an asset-light model compared with motor manufacturers.

Flat wire motor production equipment requires high requirements. In the past, it mainly relied on imports. Overseas motor production line equipment companies with more advanced technology include Italy ATOP, Germany GROB, Japan Odawara, etc. Due to the early deployment of overseas manufacturers, my country's new energy vehicle manufacturing equipment has been highly dependent on foreign technology for a long time in the past. Among them, well-known suppliers include Italy ATOP, Germany GROB, Japan Odawara Machinery Engineering Co., Ltd. and Austria Miba Group, etc., the technical level is at the first-class level, and it has the first-mover advantage. However, the price of a single line for foreign manufacturers is expensive, and an imported production line averages more than 100 million yuan.

Domestic electrical equipment supply industry is gradually localized.

2 Q: What special equipment is required for flat wire motors?

The surge in demand for drive motors drives the development of the upstream equipment industry. The motor production process is complicated and requires a large amount of special equipment. In the motor manufacturing industry, in addition to metal cutting machine tools, there are also a large number of non-standard equipment, such as special equipment for iron core punching, painting and drying; aluminum melting furnaces, preheating furnaces and die-casting machines for rotor aluminum casting, Rotor copper strip intermediate frequency welding machine; explosion-proof motor housing pressure test equipment; winding machine, bulging machine, insulation machine, dipping and drying equipment used in winding manufacturing, the quality of these equipment will affect the performance of the motor And the reliability of the work has a great influence.

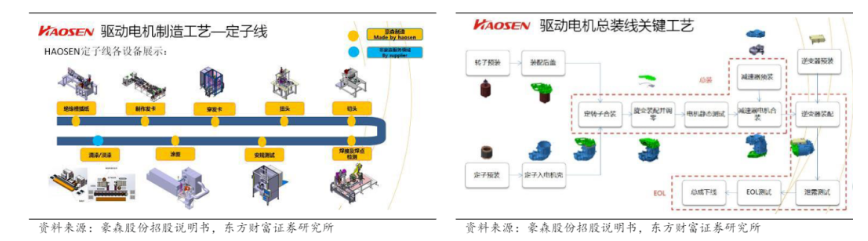

Taking the flat wire motor as an example, the production process of the automated production line includes slot paper-paper shaping-threading-threading-inserting-wire-mold-twisting-wire transfer-wire shaping-welding-dipping-painting-drying, involving production The equipment includes card issuing line equipment, card issuing and paper inserting equipment, card issuing twisting head + welding, paint dripping equipment, coating equipment, full-line automation, etc.

Above left: Schematic diagram of drive motor stator manufacturing

Above right: Schematic diagram of drive motor assembly line

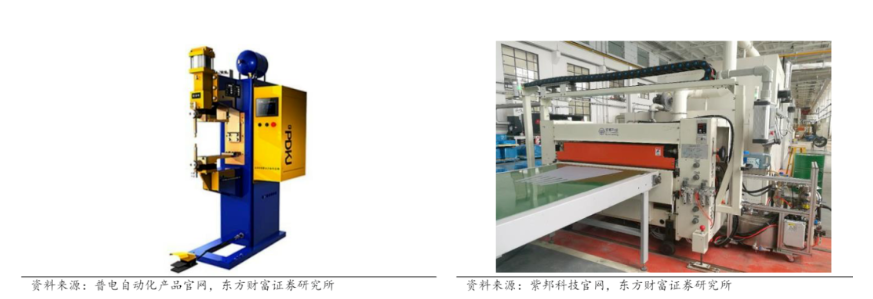

The intermediate frequency inverter DC welding machine converts the power frequency (50Hz) AC into an intermediate frequency (1000Hz) DC output. Compared with the power frequency welding machine, the time resolution and control accuracy are improved, and the output current is not affected by the secondary output circuit. Influenced by the change, the thermal efficiency is higher, the output power is large, and the welding quality is better. Compared with traditional AC welding machines, inverter intermediate frequency DC welding will be highly efficient, energy-saving, and has a very bright future development prospect. Special equipment for iron core punching, painting and drying is used for steam generator, hydro generator stator, rotor, and medium and large electric motor iron core silicon steel punching, painting, drying, cooling, splicing, stacking, forming a complete automatic painting production line, the degree of automation and equipment investment is relatively high.

Left of the picture above: The physical picture of the intermediate frequency inverter DC welding machine

Above right: The special equipment for iron core punching, painting and drying

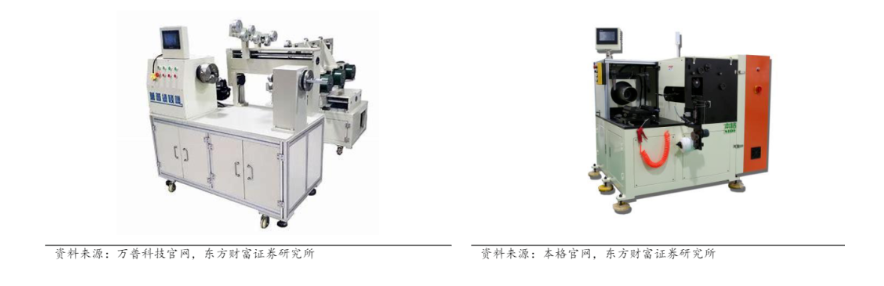

The main purpose of the card issuing and inserting machine is to use the servo motor to index, insert the insulating paper formed (double B shape, double S shape, O shape, double U shape, etc.) into the iron core slot, and automatically complete the paper feeding and heating of the insulating paper , forming, inserting into the core slot, cutting to length, transposition and other steps. The main purpose of the winding machine is to wind the inductance coil of the round wire motor. According to the degree of automation, it can be divided into a fully automatic winding machine and a semi-automatic winding machine. The fully automatic winding machine combines motors, electric components, pneumatic components, transmissions, sensors, control systems, etc. into a highly automated device, which can automatically arrange wires, wrap heads, break and clamp wires, twist wires, and load and unload; The manual operation is simple, only need to ensure sufficient raw materials and drive to replace workpieces and copper wires. The semi-automatic winding machine is currently the most widely used winding machine in my country. It can only realize automatic winding, and all other tasks need manual assistance.

Left of the picture above: The physical picture of the round wire motor winding machine

Above right: the physical picture of the flat wire motor paper inserter

3 Q: Why is the intelligentization of electrical equipment becoming a trend?

In order to improve the efficiency and power density of the motor, the number of layers of the flat wire winding is gradually increased, and the linear design is also diversified with the upgrade of the number of layers, and the customer's requirements for the degree of automation of the customized equipment increase accordingly . The automated production line can not only save labor costs and improve production tempo, but also meet the high requirements of flat wire technology for product consistency. However, due to the high threshold for the conceptual design of automated processes, only a few companies currently have fully automated production line capabilities. It is worth noting that due to the high value of single wires and the fact that the flat wire production line industry is not yet fully developed, motor manufacturers will focus on the supplier's past experience and quality of complete line delivery, so production line equipment suppliers with successful automatic line delivery cases will have First mover advantage.

From the perspective of the market structure, intelligent production has already reached a considerable scale in the world. The production automation of foreign advanced motor manufacturing enterprises' production lines and machining centers is much higher than that of China. The advanced production methods have simultaneously improved production efficiency and product reliability. China 's The level of automation and intelligence of production equipment and testing equipment is relatively backward. With the development of China's equipment manufacturing industry in the direction of high-end, precision, and cutting-edge and the integration of industrialization and informationization, it is necessary to vigorously develop intelligent manufacturing and reduce the gap with international standards. The gap between advanced manufacturing enterprises.

4Q: Is the trend of domestic substitution irreversible?

The process of domestic substitution continues to accelerate. The vigorous development of the automobile industry and the sluggishness of the equipment manufacturing industry have formed a huge contrast between the long-term dependence on overseas imports. In recent years, with the rapid rise of new energy vehicles and the increasingly fierce competition among domestic manufacturers, in order to gain an advantage in the fierce competition, domestic manufacturers have implemented cost reduction. Efficiency increases, so some domestic equipment also grows rapidly; with the rapid expansion of the emerging equipment business new energy electric drive system industry, import substitution of domestic electric drive system intelligent manufacturing equipment has become a development trend in the domestic market.

At present, domestic emerging companies and traditional round wire equipment manufacturers have broken through the technical bottleneck of flat wire equipment manufacturing, and some competitive teams in the market also have foreign investment background and production line equipment research and development experience. Therefore, in the past two years, it can be seen that the orders for flat wire motor production lines of domestic manufacturers have increased rapidly, and there is a tendency to gradually replace imported production lines. This is mainly due to new production lines focusing more on efficiency and cost-effectiveness as domestic competition intensifies. On the one hand, domestic manufacturers often have obvious cost advantages and are more competitive in the bidding process. On the other hand, foreign-funded manufacturers have slow response speed and long delivery cycle, which is a pain point that the industry knows. Tier1 enterprises and OEMs in the stage of rapid production expansion will be more inclined to choose domestic manufacturers with rapid response capabilities.

5 Q: Who are the representative companies in the electrical equipment industry?

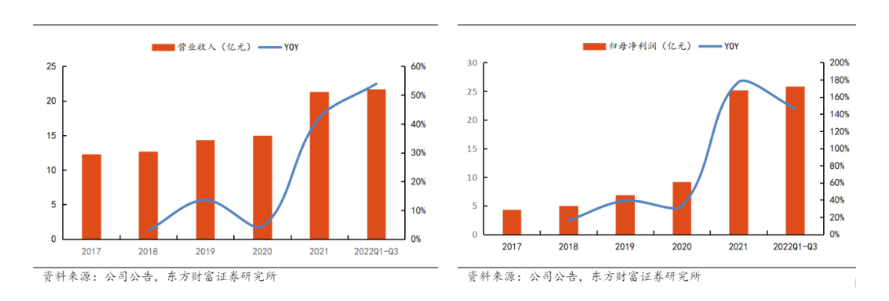

Hansoh Co., Ltd.: a leader in the intelligent manufacturing industry of automotive equipment, driven by accelerated new energy business. The company is one of the few suppliers in China that has the full-line capability of flat wire motor stator/rotor/assembly/testing. Based on the domestic leading intelligent assembly technology and process, it provides comprehensive solutions for intelligent equipment, assembly technology and complete sets of customized products. The new energy vehicle drive motor intelligent production line produced by the company is usually composed of a general assembly line, a test line, a stator subassembly line, a rotor subassembly line, a motor control subassembly line, and a gearbox subassembly line. The total length of the production line is usually 100~400 meters, the total number of production station equipment is 50~150, and various strict quality requirements are met through the station equipment; the outbreak of new energy business has made the company's energy vehicle drive motor intelligent production line business grow rapidly; focus on research and development of flat wire motor technology Equipment production line, while actively expanding the field of traditional round wire drive motor technology and equipment, has now received orders for drive motor intelligent production lines from customers such as Shanghai Loongson, Tianji Automobile, Ningbo Wei Rui Automobile, etc. In 2021, the annual revenue of the drive motor intelligent production line will be 53 million yuan. In 2022, Q1-Q3 will achieve a total revenue of 1.209 billion yuan, a year-on-year +46%. As a leading enterprise, the company will focus on smart manufacturing. With the acceleration of smart manufacturing in the future, the company's performance will continue to be positive.

Above left: Hansoh’s operating income and year-on-year growth rate

Above right: Hansoh's net profit attributable to the parent and year-on-year growth rate

Juyi Technology: equipment + electric drive two-wheel drive, the vertical extension of the production line expands the growth space. The company is a mainstream supplier of integrated solutions for intelligent equipment in advanced manufacturing fields such as domestic automobiles and core components of new energy vehicles, and is committed to building the company into an internationally competitive company in the industry around the intelligentization, electrification, and networking of the automobile industry. A leading company whose products mainly include overall solutions for smart equipment and electric drive system products for new energy vehicles. In the field of equipment, the company has successively developed high-end customer markets such as Tesla, Volkswagen, New Power, BYD, etc.; electric drive products have successively added fixed-point NIO, Ideal, Geely, etc. With the outbreak of new energy demand, the company's product performance has grown rapidly. In 2022, H1's overall solution for smart equipment will achieve revenue of 917 million yuan, a year-on-year +13.5%; in 2022, H1 will achieve a total revenue of 2.166 billion yuan, a year-on-year +5.395 billion The company closely follows the trend of new energy vehicles, plans electric drive and production line expansion through IPO, and plans to invest 673 million yuan to focus on integrated and intelligent electric drive systems, flat wire motors, oil-cooled motors, silicon carbide power modules, etc. The next-generation electric drive system will be upgraded; 154 million yuan will be raised to increase the R&D and production expansion of general industrial intelligent equipment technology.

Left of the picture above: Juyi Technology’s operating income and year-on-year growth rate

Above right: Juyi Technology's net profit attributable to the parent and year-on-year growth rate

XINDA

XINDA