The source of motor vibration and noise is indeed complex

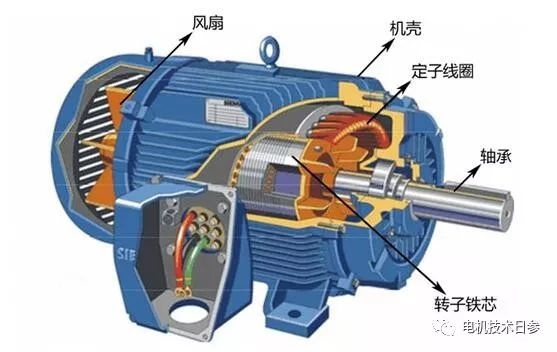

In the previous tweet, we briefly explained the vibration caused by the rotor factor. Today, Ms. participated in a brief summary of the axial vibration of the end cover and the vibration caused by the brush. In the actual manufacturing process, vibration and noise are a pair of problems that go hand in hand, especially mechanical noise, the root cause of which is vibration, that is to say, the control of mechanical noise should start with eliminating mechanical vibration.

The axial vibration of the end cover is one of the sources of mechanical noise, which is mainly excited by the vibration of the bearing, which is more important in small motors. The smaller the axial dynamic stiffness of the end cover, the easier it is to excite larger vibration speed and noise.

The vibration and noise of the brush device are caused by the poor surface condition of the commutator, the gap between the brush and the brush holder is too large, the brush pressure is too small or the brush is skewed due to improper pressure, and the brush holder, brush holder and brush rod Insufficient rigidity and other structural and technological reasons.

When the DC motor is running, the sliding contact condition of the brush and the commutator and the cuprous oxide film formed on the surface of the commutator and a layer of graphite film and dust particles covered on it not only affect the commutation performance of the motor, but also affect the commutation performance of the motor. to vibration and noise.

Practice has proved that due to the low temperature of the sliding contact surface at no-load, the above-mentioned film is not easy to form, and the dry friction between the brush and the commutator increases the noise. For example, when the no-load operation period of a steel rolling DC motor accounts for more than 50% of the total time, the noise under no-load conditions is 6~10dB higher than that under load conditions. This kind of vibration is different from the vibration caused by mechanical reasons on the surface of the commutator, which can be detected when the motor is running at low speed (touch the brush with your hand to feel the vibration). The frequency spectrum of brush vibration noise generated by sliding contact is generally in the range of 1000~-8000Hz, and it does not change much when the motor speed changes, which is one of the characteristics that distinguish it from mechanical reasons.

The brush vibration noise generated by the sliding contact is also related to the polarity of the brush. For example, the positive brush of a DC generator has less vibration than the negative brush; because the positive brush can separate graphite and carbon crystals, absorb moisture on the surface of the commutator to form a lubricating film, while the negative brush removes it. The formation of the sliding contact film is also related to the brand of the brush. The choice of the brand is first to ensure good commutation performance, but at the same time the vibration and noise of the brush should also be considered.

In addition to mechanical noise, aerodynamic noise is also a major problem in motor noise control. Especially for high-speed motors, this problem is relatively concentrated. In the tweets after acceptance, Ms. participated in the meeting and chose some content to share with you.

XINDA

XINDA