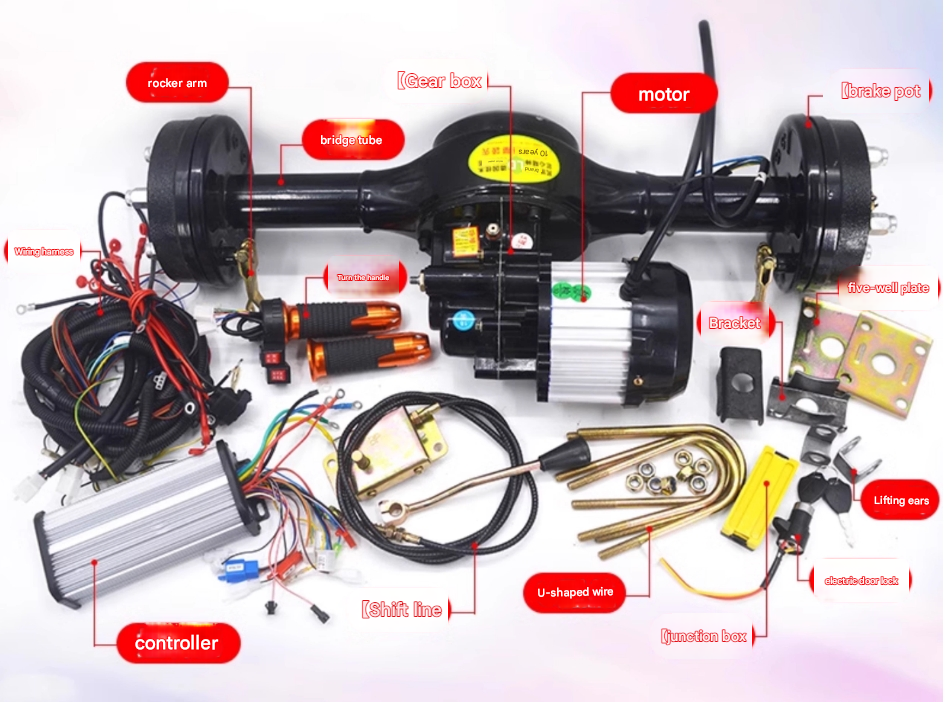

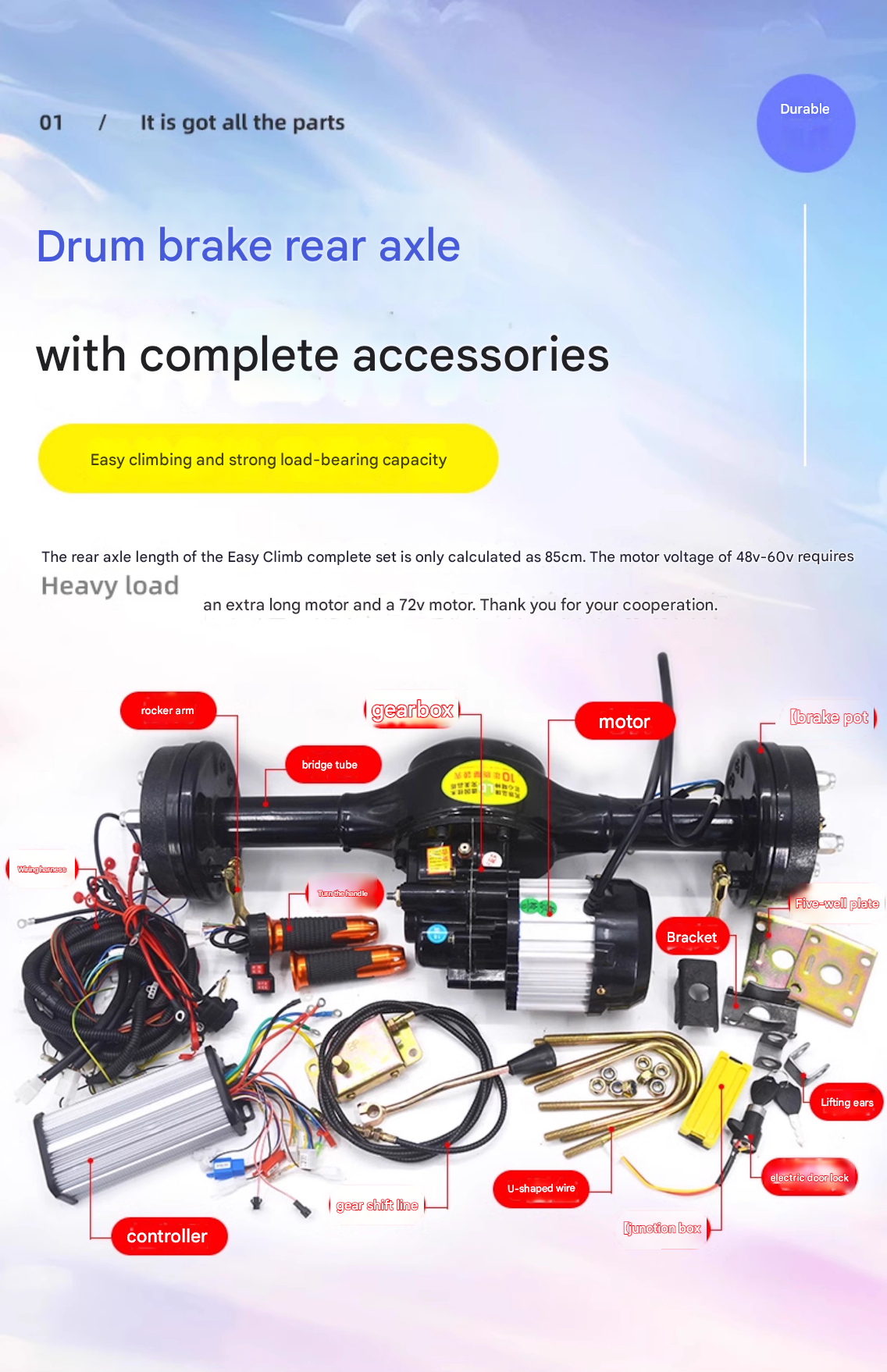

Electric tricycle rear axle assembly Hongrunda high speed motor drum brake shift high power full set

#tricycle #rearaxle

Sort by type:

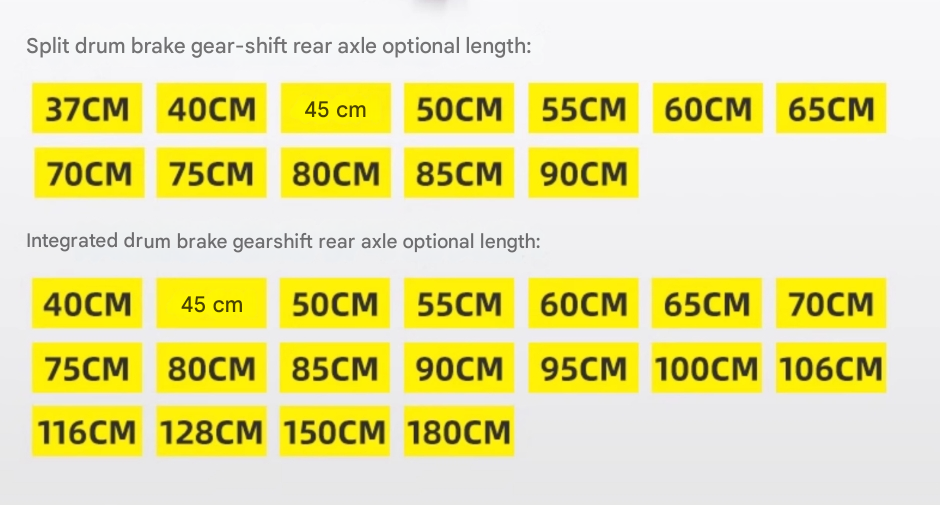

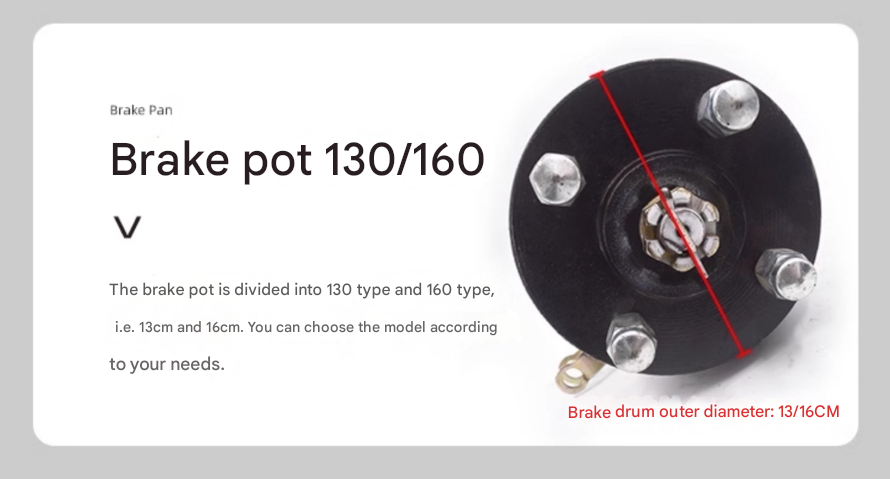

Split drum brake gear-shift rear axle 30-40-50-60-70-80-85cm

Integrated drum brake gear shift rear axle 50-55-60-65-70-75cm

Integrated drum brake gear shift rear axle 70-75-80-85cm

Integrated drum brake gear shift rear axle 90-95cm

Integrated drum brake gear shift rear axle - 100-106cm

Integrated drum brake gear shift rear axle 110-118-120-125cm

Integrated drum brake gear shift rear axle 128-138cm

Integrated drum brake gear shift rear axle 150-160-180cm

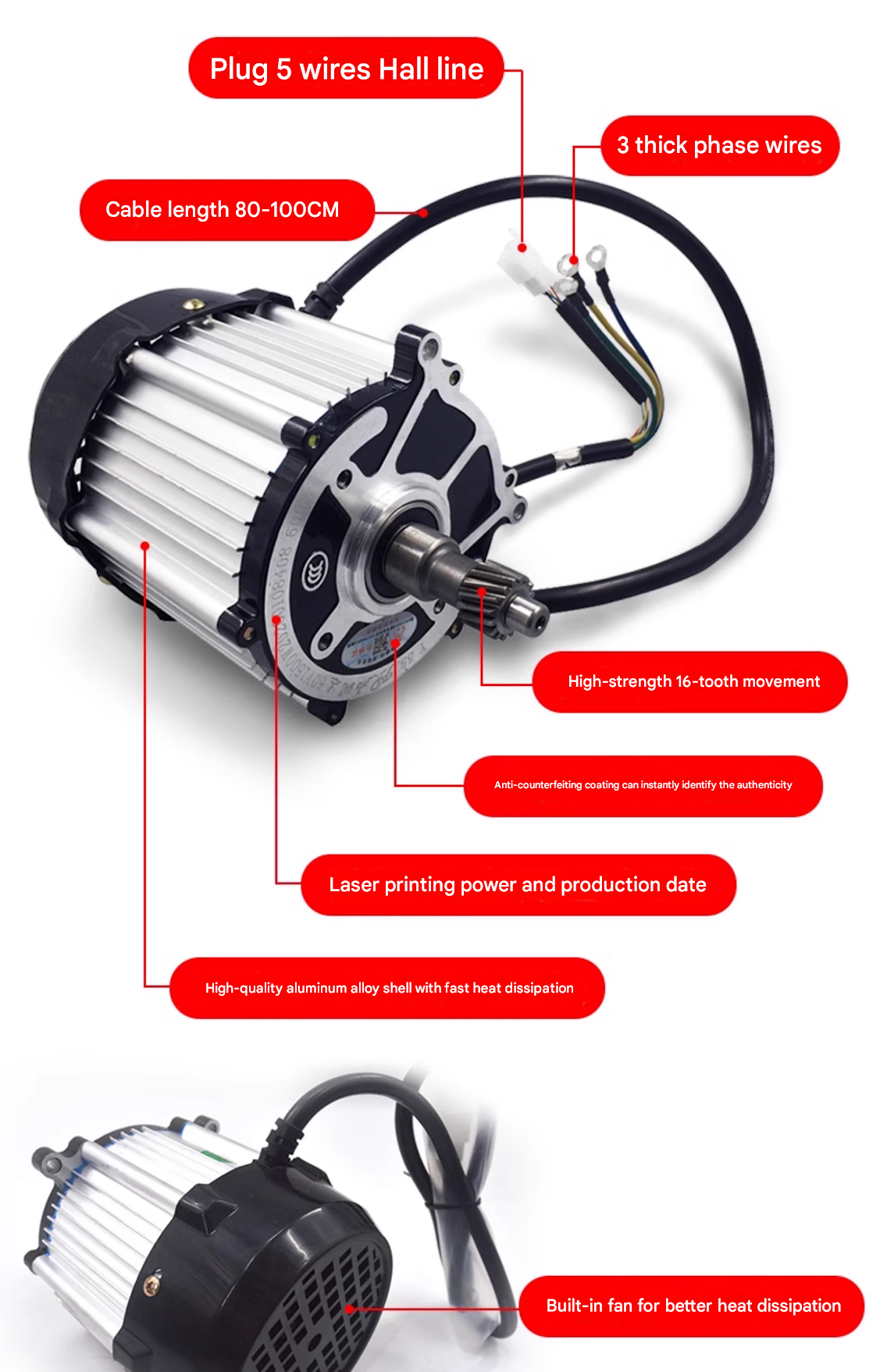

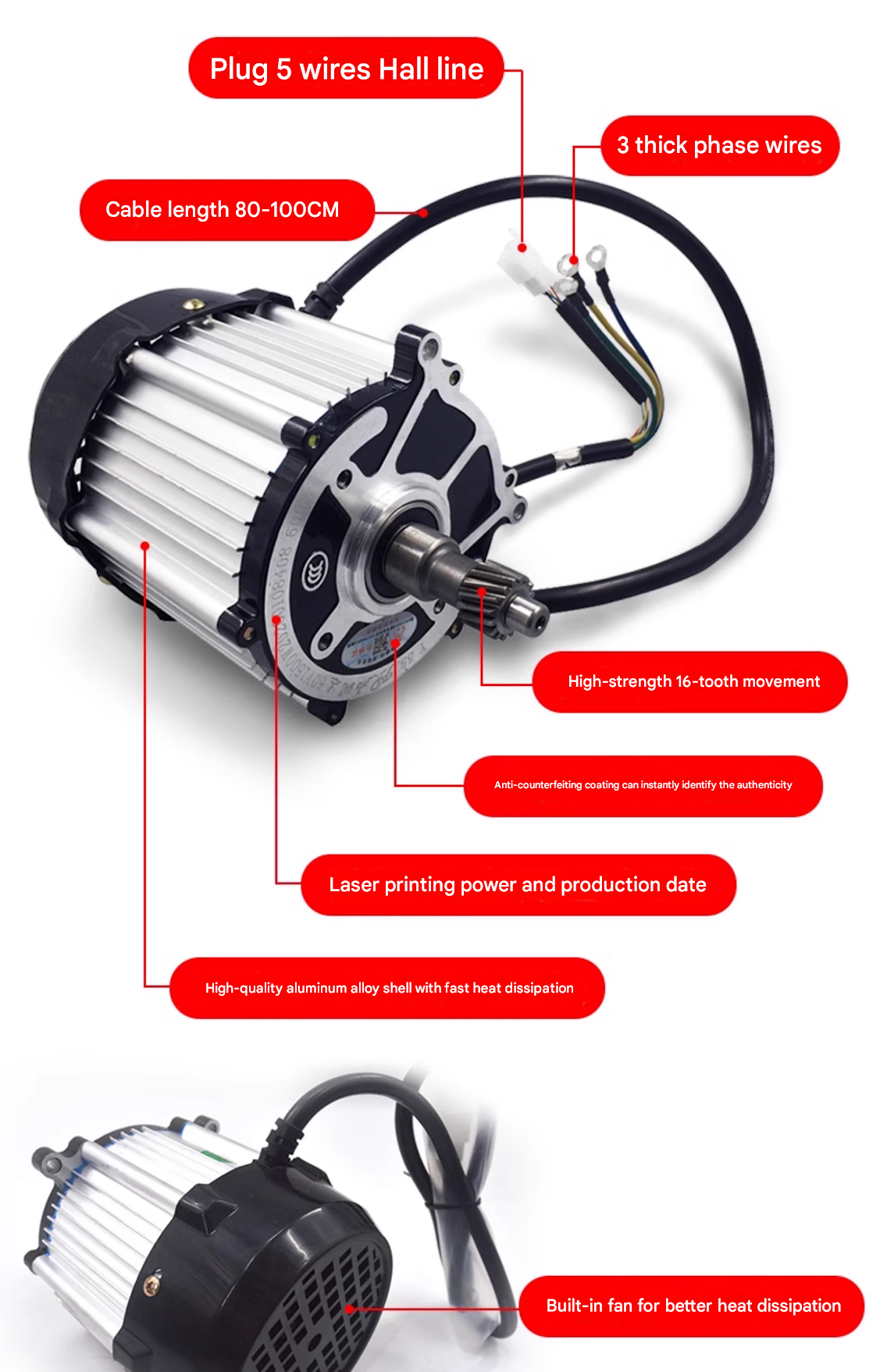

Integrated power system/wiring harness+lock+throttle+12G controller+motor 500W

Integrated bridge power system/wiring harness+lock+throttle+12G controller+motor 650W

Integrated bridge power system/wiring harness+lock+throttle+15G controller+motor 800W

Integrated bridge power system/wiring harness+lock+throttle+18G controller+motor 1000W

Integrated bridge power system/wiring harness+lock+throttle+24G controller+motor 1200W

Integrated bridge power system/wiring harness+lock+throttle+24G controller+motor 1500W

Integrated bridge power system/wiring harness+lock+throttle+30G controller+motor 1700W

Split power system/wiring harness+lock+throttle+12G controller+motor 500W

Split bridge power system/wiring harness+lock+throttle+12G controller+motor 650W

Split bridge power system/wiring harness+lock+throttle+15G controller+motor 800W

Jusong high speed 4000 rpm/integrated bridge power system full set 1000W

Jusong high speed 4000 rpm/integrated bridge power system full set 1200W watt

Jusong high speed 4000 rpm/integrated bridge power system full set 1500w watt

Jusong high speed 4000 rpm/integrated bridge power system complete set 1800WW

Jusong high speed 4000 rpm/integrated bridge power system full set 2200wW

Jusong high speed 4000 rpm/integrated bridge power system full set 2500W

Electric tricycle rear axle assembly video:

https://youtube.com/shorts/5Zx_d1OZoGw?feature=share

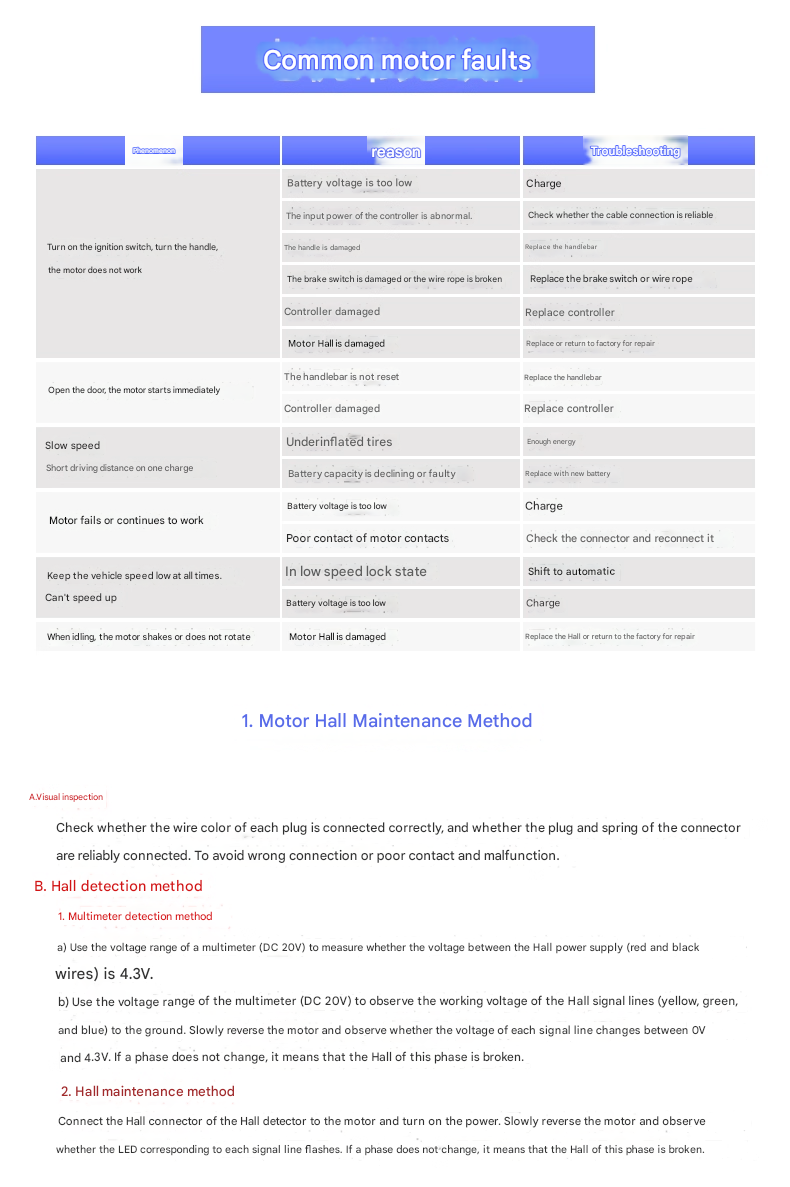

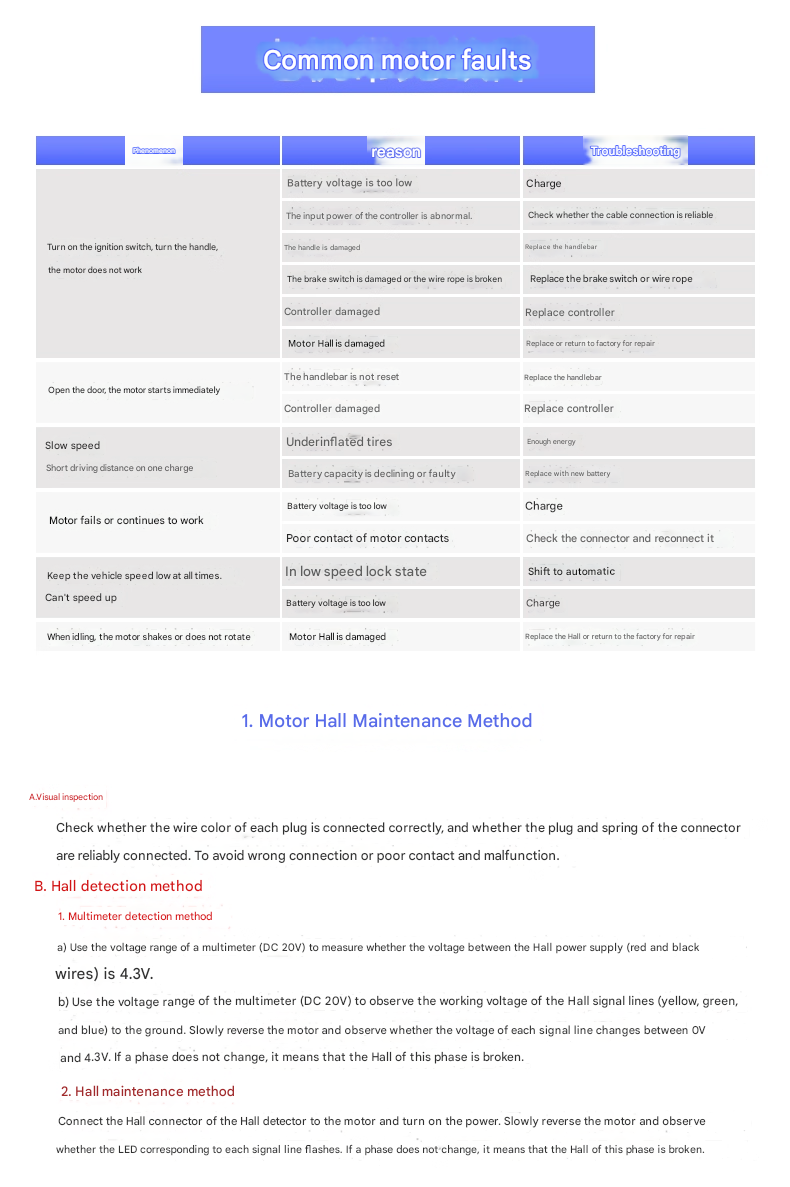

1. Motor Hall Inspection Method

A. Visual Inspection

Check whether the wire color of each plug is connected correctly, and whether the plug and spring of the connector are reliably connected. To avoid wrong connection or poor contact and failure to work properly. B. Hall Detection Method

1. Multimeter Detection Method

a) Use the multimeter voltage range (DC 20V) to measure whether the voltage between the Hall power supply (red and black wires) is 4.3V.

b) Use the multimeter voltage range (DC 20V) to observe the working voltage of the Hall signal line (yellow, green and blue) to the ground. Slowly reverse the motor and observe whether the voltage of each signal line changes between 0V-4.3V. If a phase does not change, it means that the Hall of this phase is broken.

2. Hall Inspection Method

The Hall connector of the Hall detector is connected to the motor and the power is turned on. Slowly reverse the motor and observe whether the LED corresponding to each signal line flashes. If a phase does not change, it means that the Hall of this phase is broken.

2. Controller maintenance method

A. Measurement when not connected

When the controller is not connected to any plug, use the multimeter resistance range (200K) to measure the resistance between the three phase lines. Normally, it should be greater than 18K. If it is less than 18K, it can be basically determined that the power tube is burned out.

B. Visual inspection

Visual inspection is mainly to check whether the wire color connection of each plug is correct before power is turned on. To avoid wrong connection and burning the controller.

C. Multimeter measurement after the actual vehicle is powered on

1. Phenomenon: Turn the handle, the motor does not turn

Repair process: (for example, 60V motor)

a) Use the multimeter voltage range (DC 200V) for 60V batteries. Measure whether the power line and the electric door lock line have 60V. If there is no 60V, check whether the vehicle power cable is in normal contact. The power supply voltage of other specifications is consistent with the battery pack voltage.

b) Check the brake circuit to see if it is in the braking state (the tail car will light up when braking). You can use a multimeter to check whether the brake level changes.

C) Check whether the motor Hall is normal. You can refer to the motor Hall detection method. d) Use the voltage range of the multimeter (DC 20V) to measure whether the voltage between the throttle power supply (red and black wires) is 4.3V. If there is no 4.3V, it means that there is a problem with the power supply inside the controller. e) Use the voltage range of the multimeter (DC 20V) to measure the voltage between the throttle signal line (green) and the ground (black (measured on the controller output line). When the throttle is turned, this voltage should change linearly between 0.8V-4.2V to be normal. If the voltage remains unchanged, you can replace a throttle and try again. If the fault cannot be solved, replace the controller.

2. Phenomenon: Always running in low gear and unable to change to high gear. Repair process:

a) Check the low-speed lock line and see if the gray line and the black line are short-circuited. When short-circuited, it is low-speed lock and this connector can be unplugged. See if it can be converted normally. b) Use the voltage range of the multimeter (DC 20V) to measure whether the battery voltage is lower than the battery undervoltage value under load. If the battery voltage is too low, it may not be converted. This is normal. It is mainly to protect the battery from being damaged when it is discharged under voltage. It is recommended to re-verify with a fully charged battery.

Note: After the rear axle is installed, please debug it before going on the road. Once the vehicle is on the road, any traffic accidents will be borne by yourself. Please make sure that the product is installed and debugged properly before using it.

How to buy and maintain the motor and rear axle controller?

1. For a load of more than 1,000 jin, 1000w, 1200w, 1500w, etc. are recommended. For a load of 1 ton, 1500 watts or more are recommended. If you buy a smaller one, the motor controller will easily get hot.

2. The split is recommended to be within 1,000 jin. For a load of more than 1,000 jin, it is recommended to buy an integrated one. For a ton, it is recommended to buy a full floating one with 6 teeth. Pay attention to the weight to choose the model that suits you.

3. Large items are 40-50 kilograms. We usually send them by express delivery. It is inevitable that there will be bumps and scratches. This cannot be avoided. Those with high requirements will not buy them. Please note that this phenomenon is not a quality problem.

4. Lead-acid batteries are recommended for this motor controller. Please pay attention to purchase!

5. Please test the length size according to the measurement method on the webpage to avoid purchasing the wrong one and not being able to use it.

Contact sales:

Whatsapp: +86 133 6158 0392

Wechat/mobile: +86 18615338538

Wechat name: xdmotor

Email 1: sales@xdmotor.tech

Email 2: xindamotor@gmail.com

Company website:

https://www.xindamotor.com

https://www.xdmotor.tech

Home

Home  EV KITS

EV KITS

Electric Tricycle kits

Electric Tricycle kits Four-wheelers kits

Four-wheelers kits EV Motor

EV Motor

Oil Pump Motor

Oil Pump Motor EV Driving Motor

EV Driving Motor EV and auto parts

EV and auto parts Conversion Kits

Conversion Kits XD Motor

XD Motor

XD DC Motor

XD DC Motor XD AC Motor

XD AC Motor Industrial Motors

Industrial Motors Motor Drive Machines

Motor Drive Machines Knowhow

Knowhow  About XD

About XD

Company Profile

Company Profile Honor

Honor Factory Appearance

Factory Appearance XINDA Team

XINDA Team Events

Events

Summit

Summit Clients Visit

Clients Visit Exhibition

Exhibition Contact

Contact

XINDA

XINDA