The 4 major advantages of slotless BLDC motors over slotted BLDC motors

Over the past decade, brushless DC motors (BLDC) have increasingly replaced brushed DC motors, especially in applications where high speed (12,000 rpm and above) and long service life are required.

But brushless DC motors do not have all the advantages: brushless DC motors provide simple control and no cogging effect, while the complex structure of brushless DC motors means higher costs - conventional brushless DC motors are slotted in design , that is, the coil is wound in the slot around the stator.

As a result, a brushless DC motor with a slotless design was developed, which has four major advantages over conventional slotted brushless DC motors.

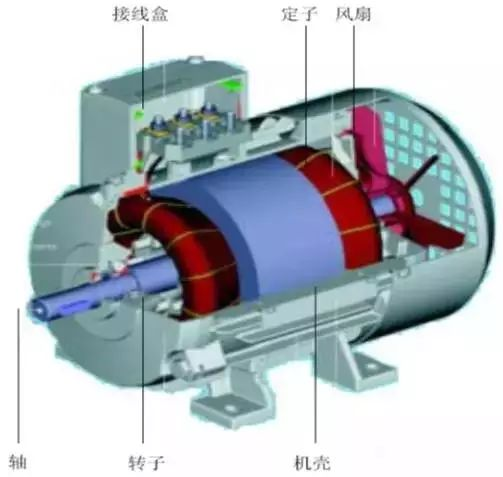

Slotless BLDC motors feature a slotless design where the coils are wound in a separate external operation and then inserted directly into the air gap during motor assembly.

Advantage 1: The slotless BLDC motor can be smaller in size.

In slotted brushless DC motors, the presence of stator teeth prevents the overall size of the motor from being minimized. Additionally, as motor sizes shrink, the winding process becomes progressively more difficult. In contrast, slotless brushless DC motors have diagonal or axial windings fixed on a cylindrical stator core, making it easier to downsize.

Advantage 2: Slotless BLDC motor costs less

The slotless design also has cost advantages because it reduces complexity and the stator core is easier to manufacture.

Advantage 3: Slotless BLDC motor has high power density

While both designs can operate at much higher speeds than brushed DC motors, the slotted and slotless designs have different characteristics at high speeds. To obtain mechanical stability at high speed operation (from 40,000 to 60,000 rpm), usually slotless rotors have a two-pole permanent magnet design. In addition, due to the existence of the large air gap, when the motor runs at high speed, the loss of the stator core is limited to an acceptable range. This means that the slotless BLDC motor benefits from the slotless stator structure and has relatively small core losses, so it has high power density.

In fact, in the early days of slotless BLDC motor design, its power density was lower than that of equivalent slotted motors. However, the advent of high-energy permanent magnets and their alternative magnetizing devices has narrowed the performance gap. Slotted brushless DC motors are less suitable for use with high energy magnets because the thicker teeth required to increase the magnetic load on the motor have the effect of reducing the area of the slot and thus the electrical load on the motor.

Advantage 4: Slotless BLDC motor has better overload

Slotted brushless DC motors can provide higher torque than slotless designs because slotted designs can handle higher temperatures, allowing more torque to be produced. However, the torque of the motor is reduced due to saturation of the magnetic circuit during overload operation, and the toothless design has no magnetic saturation and therefore provides better overload.

Although slotless BLDC motors have many advantages over standard BLDC, in practical applications, slotless BLDC motors are not always the best choice. For example, slotless BLDC motors offer low inductance, which poses motion control challenges. If pulse width modulation (PWM) control is used, low inductance results in higher motor losses. Control devices with higher switching frequencies (80 to 100 kHz) or series compensation inductors can be used to alleviate the low inductance problem.

In fact, different brushless DC motor technologies are suitable for different applications. Slotted brushless DC motors are suitable for applications such as electric vehicles or home appliances where a higher pole count is required and final size is not an issue. They are also preferred in harsh environments because the slotted design coils are easier to protect and are mechanically held in place by the stator teeth. And for applications that require high speed and small size, such as in medical equipment or portable industrial tools, slotless BLDC motors are a better choice and can provide the best solution.

XINDA

XINDA