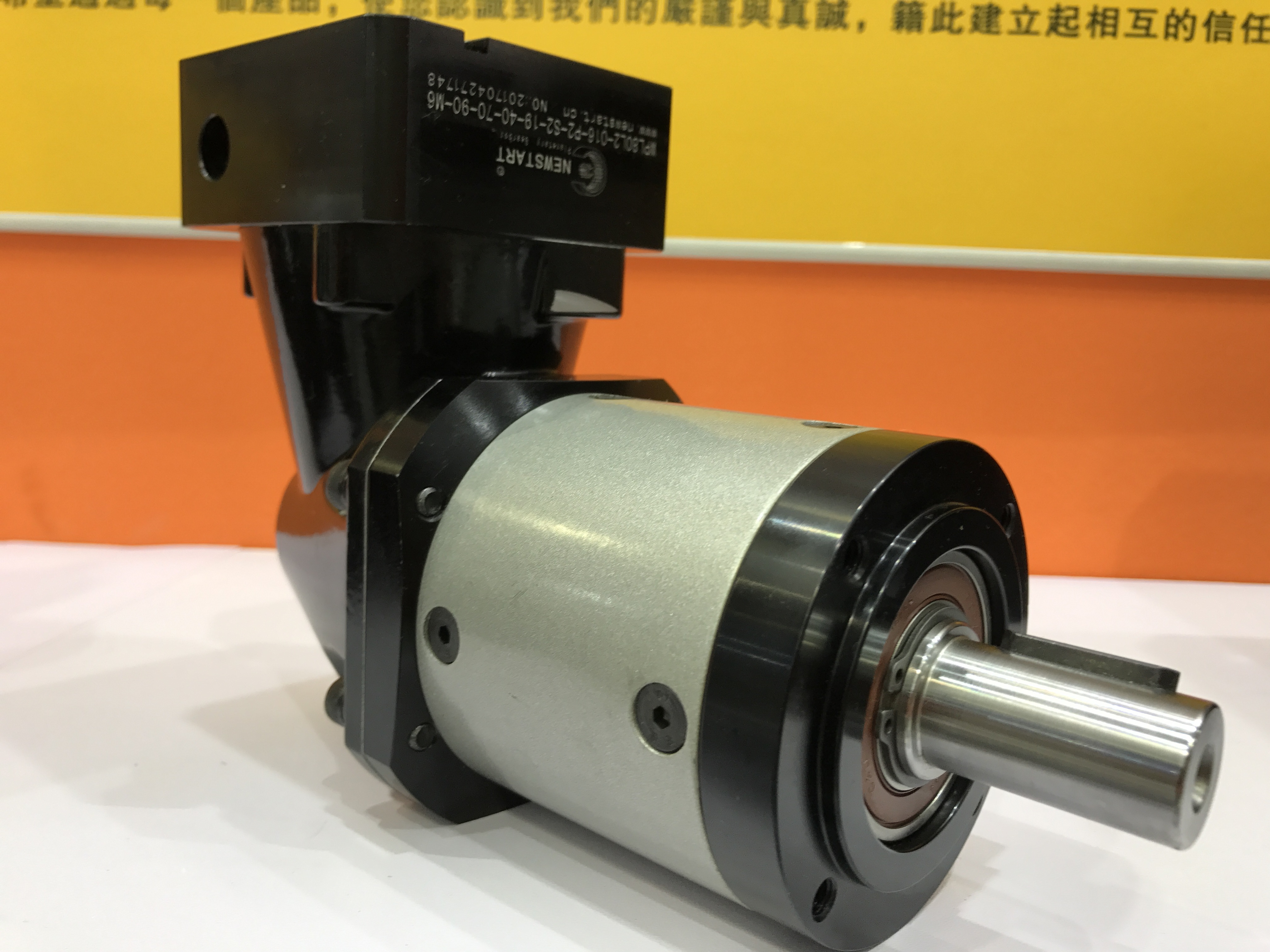

Lubrication principle of planetary gear reducer

The operation of the planetary gear reducer requires maintenance and replenishment of lubricating oil to improve efficiency, quality and service life. If you need to know, please refer to the following: lubrication method of planetary gear reducer, cause of oil leakage of planetary reducer, lubrication and maintenance of planetary reducer. Today, we introduced the relevant knowledge of the lubrication principle of the planetary gear reducer.

The principle of lubricating oil is to reduce friction. Friction is the relative contact between two moving surfaces when they are displaced by an external force. There are many types of friction, including external friction, internal friction, sliding friction, rotational friction, dry friction, boundary friction, fluid friction, and mixed lubrication. Friction creates obvious situations such as low temperature, low pressure, music and wear. The main hazards are wear, including adhesion, abrasive particles, decay and nominal fatigue. These wear and tear directly affect the normal operation and even efficiency of mechanical equipment.

The role of lubricating oil is to form a protective film between the two friction pairs to prevent direct contact between metals. This reduces friction and smoothens, which reduces wear. The maintenance film can be a physical adhesion film, a chemical adsorption film or an oxide film. Film thickness and strength directly affect lubrication.

The lubrication method of the planetary gear reducer is as follows:

1. Splash lubrication method: the gear in the reduction box is sealed on the reduction box at a high speed (5m/s).

2. Lubrication point pressure lubrication method: add the oil pump to the engine, and supply lubricating oil to the gear through the pressure of the oil pump. The pressure lubrication method belongs to forced lubrication, which relies on the oil pump to deliver the lubricating oil to the friction pair under a certain pressure. Typically, plunger pumps are used for lubrication. The plunger pump is installed in the housing, and its reciprocating motion is used to supply oil.

3. Spray lubrication method: pressurize directly, and use an oil pump to spray through the nozzle. This method is suitable for closed gears with peripheral speed greater than 12~14m/s and low splash lubrication efficiency.

4. Oil drop lubrication method: use the weight of lubricating oil to drop a drop of oil on the friction pair.

5. Oil ring lubrication: A method of lubrication in which a ring with a diameter larger than that of the shaft rotates with the shaft, bringing lubricating oil from the oil reservoir to the journal.

The lubrication of the planetary gear reducer can reduce the transmission wear of the gear reducer and prevent the friction parts from rusting. As a maintenance method, the lubricating oil should be changed periodically as needed.

1. Fuel tank pressure rises

In an enclosed reducer, the friction between each pair of gears generates heat over time. Boyle-Maloter's law allows this to happen. While maintaining speed, gradually increase the temperature in the reduction gearbox. Therefore, as the pressure of the container increases, the lubricating oil will escape from the box and overflow onto the inner wall of the reducer housing. Since oil is very water permeable, under pressure anywhere in the tank is not tight enough to leak out.

2. Unscientific structural design of the reducer leads to oil leakage

If the gear unit does not have a ventilation cover, pressure equalization cannot be achieved. This will cause the pressure to build up in the container, causing oil to leak.

3. Too much fuel

During the operation of the reducer, the oil pool is severely agitated. Lubricating oil spills out of the machine. If too much oil is added, a large amount of lubricating oil will accumulate, causing leakage at shaft seals, joints, etc.

4. Improper maintenance techniques.

During equipment maintenance, oil leakage is caused by improper dirt removal, improper use of sealants, incorrect installation of sealing elements, and untimely replacement of sealing elements.

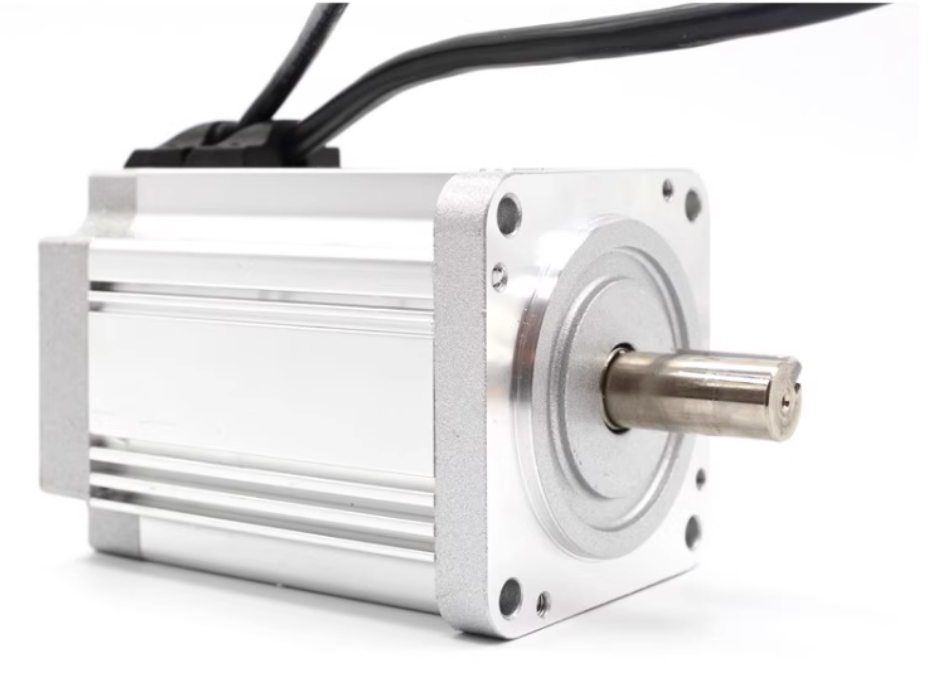

Lubrication and maintenance of planetary reducer

Install the recommended type and value of grease into the planetary reducer. The planetary reducer should be lubricated with lubricating oil. Since the lubricating oil of the planetary reducer may not ensure reliable lubrication of the top bearing, another lubrication method is selected.

Before operation, inject lubricating oil into the planetary reducer. The choice of viscosity depends on the following categories. Planetary reducers are usually equipped with oil filling holes and oil drain plugs. Therefore, the installation position of the planetary reducer should be determined at the time of purchase.

The lubricating function of general lubricating oil is to form an oil film between friction surfaces to protect them. The method of lubricating oil depends on additives forming adsorbents

XINDA

XINDA