Barriers, pricing models and development space calculations for flat wire motors!

According to the cross-sectional shape of the magnet wire, we divide the magnet wire into round wire and flat wire. According to the insulating layer material and application on the surface of the magnet wire, we can divide the magnet wire into enameled wire, wrapped wire, inorganic insulated magnet wire and special magnet wire. At present, enameled wire and wrapped wire are mainly used in the field of new energy vehicles.

Enameled wire: Enameled wire is coated with insulating varnish on copper wire, and after drying, a layer of paint film is formed as an insulating layer. Common paint film materials include acetal, polyurethane, epoxy, polyesterimide, etc.;

Wrapped wire: Wrapped wire is tightly wrapped on copper wire or enameled wire with insulating paper, glass fiber, natural silk and synthetic wire to form an insulating layer, including silk-wrapped wire, glass-wrapped wire, paper-wrapped wire, and film-wrapped wire wait.

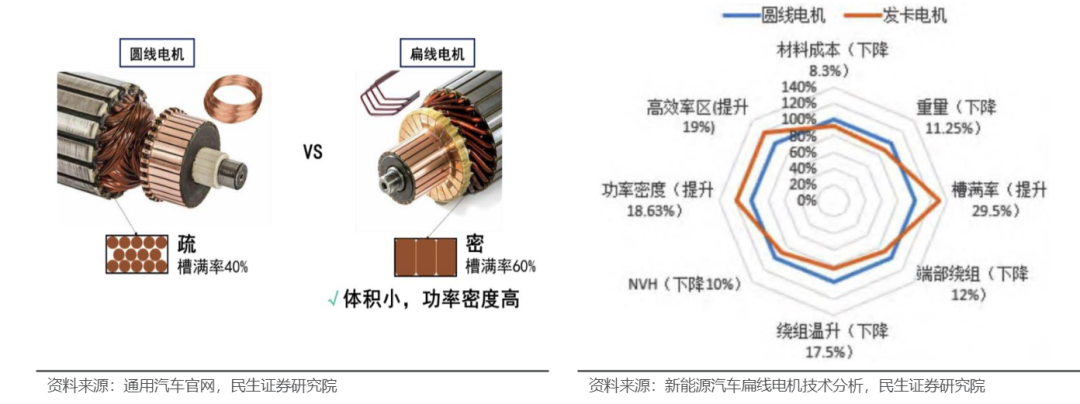

Above left: Structural schematic diagram of round wire motor and flat wire motor

Above right: Schematic diagram of performance comparison between flat wire motor and round wire motor

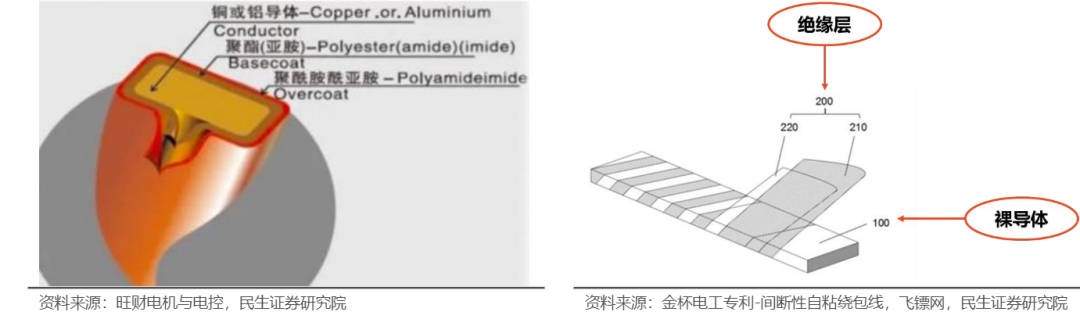

Above left: Schematic diagram of enameled wire structure

Above right: Schematic diagram of wrapping wire structure

flat line barrier

The barrier of flat wire can be discussed in two aspects: copper wire and insulation layer.

-

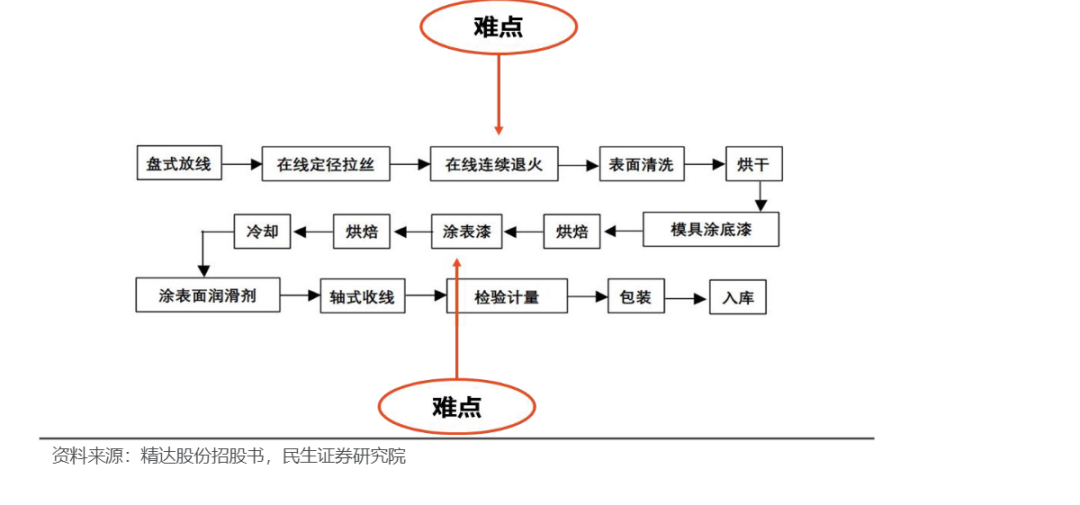

Copper wire : For copper wire, consistency and accuracy are two core elements. The process of flat wire is more complicated. High consistency and high accuracy are the key to the stable operation of the motor. Therefore, the flat wire process requires equipment higher. On the other hand, the flexibility of the copper wire is also a key parameter. Switching from a circular shape to a rectangular shape requires higher flexibility of the copper wire. Therefore, multiple annealing treatments are required to reduce the hardness of the copper wire and improve the elasticity of the copper wire.

-

Insulation layer: For flat wires, the uniform coating of the insulation layer is the main barrier, because the cross-section of the flat wire is rectangular, when coating, due to the existence of four 90-degree R angles, the coating paint is subject to gravity. The influence tends to spread toward the middle, resulting in thinning of the coating layer at the four R corners, so that the uniformity is impaired.

-

The 800V high-voltage platform puts forward higher requirements for the insulation layer: Under the 800V voltage architecture, higher requirements are required for the voltage breakdown resistance of the insulation layer. Mainly reflected in two aspects:(1) The thickness of the insulating layer becomes thicker;(2) Changes in the formula of insulating varnish, such as the PEEK coating (polyether ether ketone insulating layer) introduced by Jingda for high-voltage platforms, which can withstand voltage platforms exceeding 1000V.

Above: Schematic diagram of the magnet wire production process

Flat Line Pricing Model

The pricing model of electromagnetic wire is mainly a cost-plus model, that is, the company earns processing fees for copper wires. For ordinary round wires, the processing fee in the current market is about 0.5-0.8 million yuan/ton, while for flat wires, due to the higher precision requirements of copper wires for flat wires, the insulation layer formula is upgraded, and the processing technology is more advanced. It is complicated, so the processing fee of flat wire is relatively higher, and the processing fee in the current market is about 15,000-20,000 yuan/ton. (Note: The above price calculation is only the price in 2022 at the time of publishing this article. Everything depends on the actual market and is for reference only.)

Space Calculation of Flat Lines

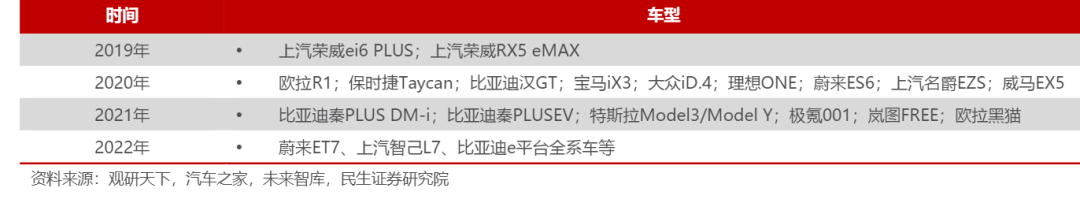

The advantages of flat wire motors are outstanding, and mainstream models have been equipped with them. Various OEMs have been intensively deploying flat-wire motor business. Best-selling models such as Tesla Model 3/Y, BYD DM-i, BYD Qin PLUS EV, Volkswagen iD.4, and Jikr 001 are equipped with flat-wire motors. The demand in the new energy vehicle industry is booming, the penetration of flat wire motors will continue to accelerate, and the drive motor industry will usher in a rise in volume and price, with considerable room for growth.

Above: List of models equipped with flat wire motors (partial)

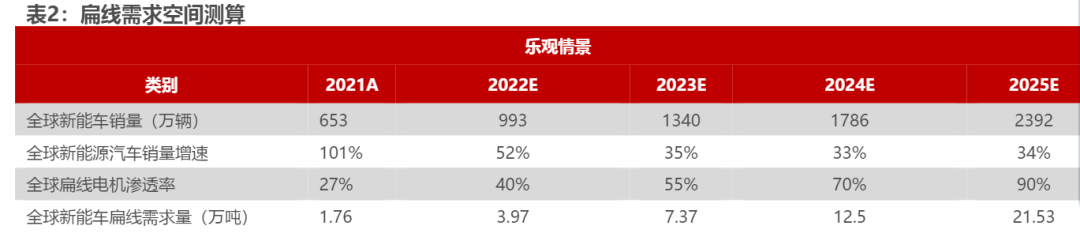

For spatial calculation, we make the following core assumptions:

-

The bicycle is equipped with a flat cable with a weight of 10KG;

-

Penetration rate of flat wire motors in the field of new energy vehicles: According to the data of Huajing Industry Research Institute, the penetration rate of flat wire motors in the field of new energy vehicles in 21 years is about 27%. We expect that in an optimistic scenario, 22/23/24/25 The annual penetration rates of flat wire motors in the field of new energy vehicles are 40%/55%/70%/90%; under the neutral scenario, the penetration rates in 22/23/24/25 are 30%/36%/42% respectively /50%.

-

According to the data of 2020/21, the demand for flat wires in other fields and the demand for flat wires for new energy vehicles account for about 3:5. Namely: the demand for flat wires in other fields is 0.6 times the demand for flat wires in the field of new energy vehicles.

Based on the above assumptions, we predict that by 2025, under the optimistic scenario, the global flat wire demand will reach 344,500 tons, and the four-year CAGR from 21 to 25 years will be 87.02%; under the neutral scenario, the global flat wire demand will be It reached 191,400 tons, and the four-year CAGR from 21 to 25 was 61.39%.

Above: Calculation of space demand for flat wires

XINDA

XINDA