Self-adhesive iron core for motor efficiency improvement

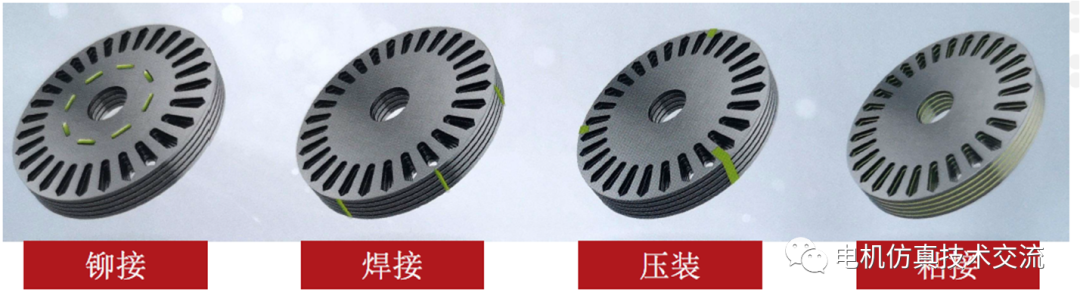

A self-bonded core is a core formed by bonding laminations together with an adhesive, and the choice of stacking technique depends on motor design and economic considerations. The lamination process is divided into technologies in the stamping process (self-fastening, spot welding, self-adhesive) and downstream technologies of the stamping process (welding, rivets, self-adhesive).

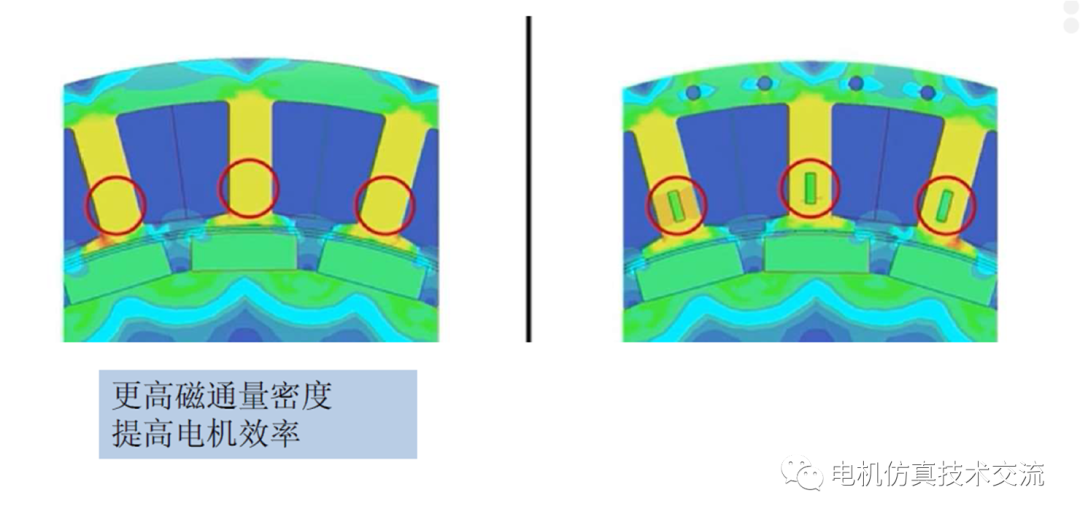

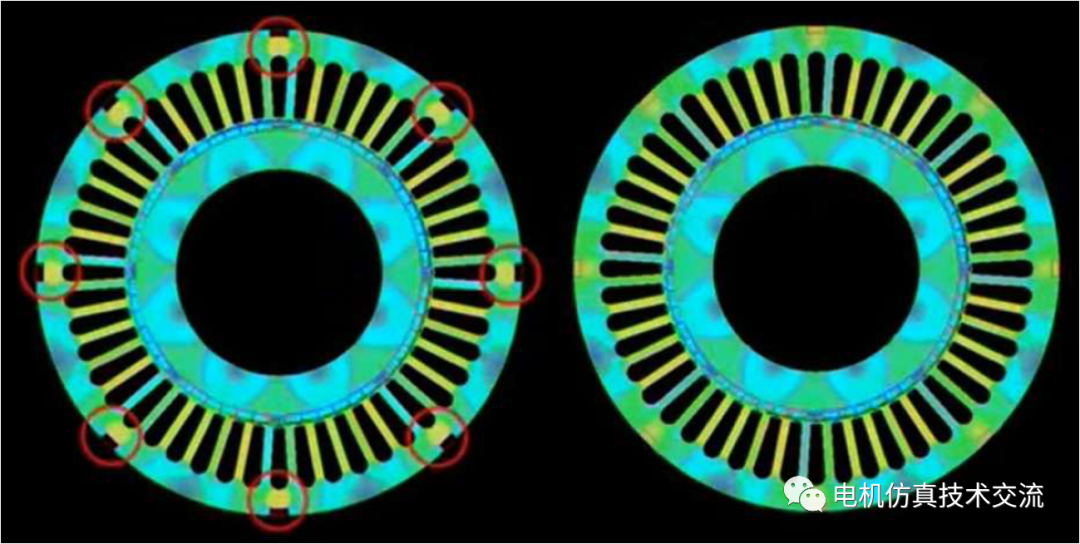

Iron core can be freely designed without considering the reserved riveting and welding positions;

Allows the electrical engineer the freedom to design for the desired motor performance without having to take into account manufacturing aspects such as snap-in or weld seam locations. This makes it possible to design more energy-efficient electric motors.

Bonding strength is extremely high, forming a whole;

Since the laminations do not self-fasten and expand, tighter tolerances and shape stability can be controlled. During the self-adhesive process, the problem of tension in the welded part of the core due to heat introduced during welding does not occur.

flux of complete silicon steel sheet due to no welding seam and no punching hole;

Bonding has no effect on the magnetic properties of electrical steels. In contrast, self-clamping and welding can severely disrupt the microstructure, compromising the material's magnetic properties.

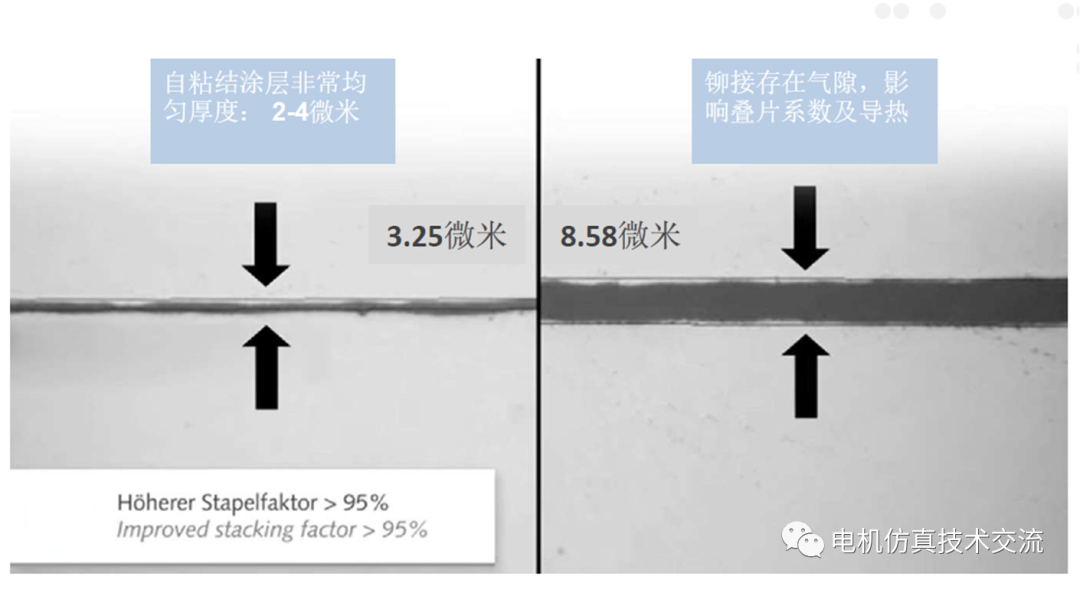

the thermal conductivity, there is no air gap between the punches, and each punch is completely bonded;

Improved heat dissipation through improved heat transfer between the laminations and the case allows cooling devices to be made smaller, making them lighter, smaller and less expensive.

Reduce running noise;

A self-bonded core effectively dampens vibrations in the laminations to minimize sound levels.

the same low iron loss and high efficiency as scattered chips;

has a higher lamination coefficient than loose sheets.

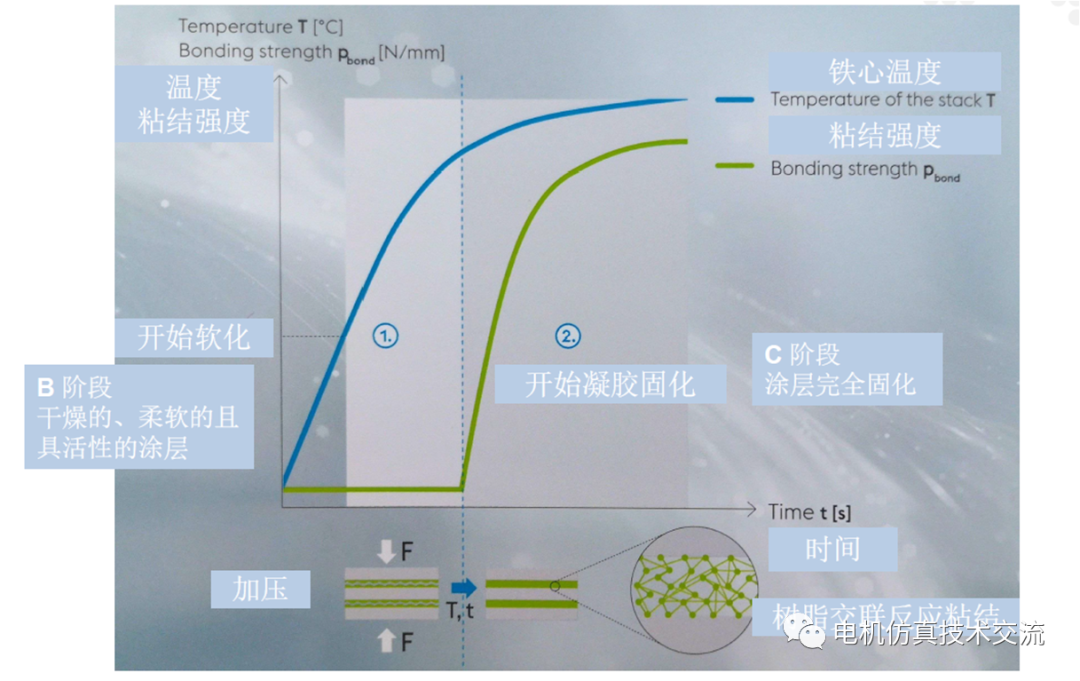

Technology to bond the punched sheets together under heating and pressure;

Interlayer loss caused by riveting and welding;

Bonded iron core has very good thermal conductivity and no AC noise;

Will not "breathe" with temperature changes, avoiding interlayer corrosion;

Bonding coating also has the function of interlayer insulation.

Self-adhesive

The magnetic field distribution of the self-adhesive sheet is more uniform

Simultaneously improve lamination coefficient and thermal conductivity

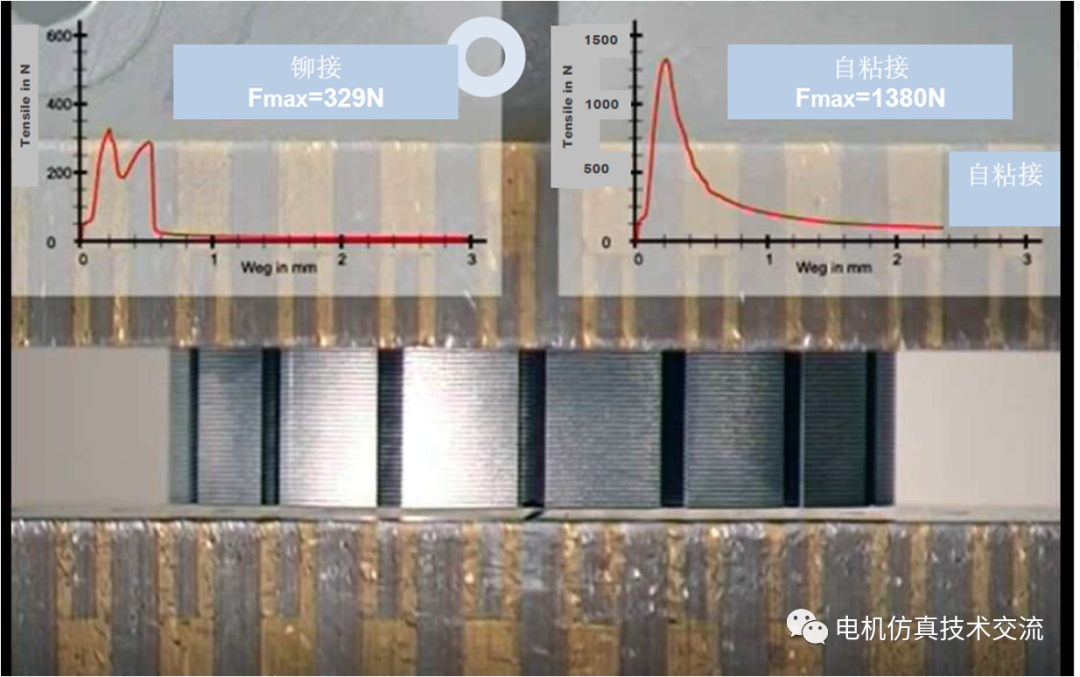

Core strength comparison

bonding heating process

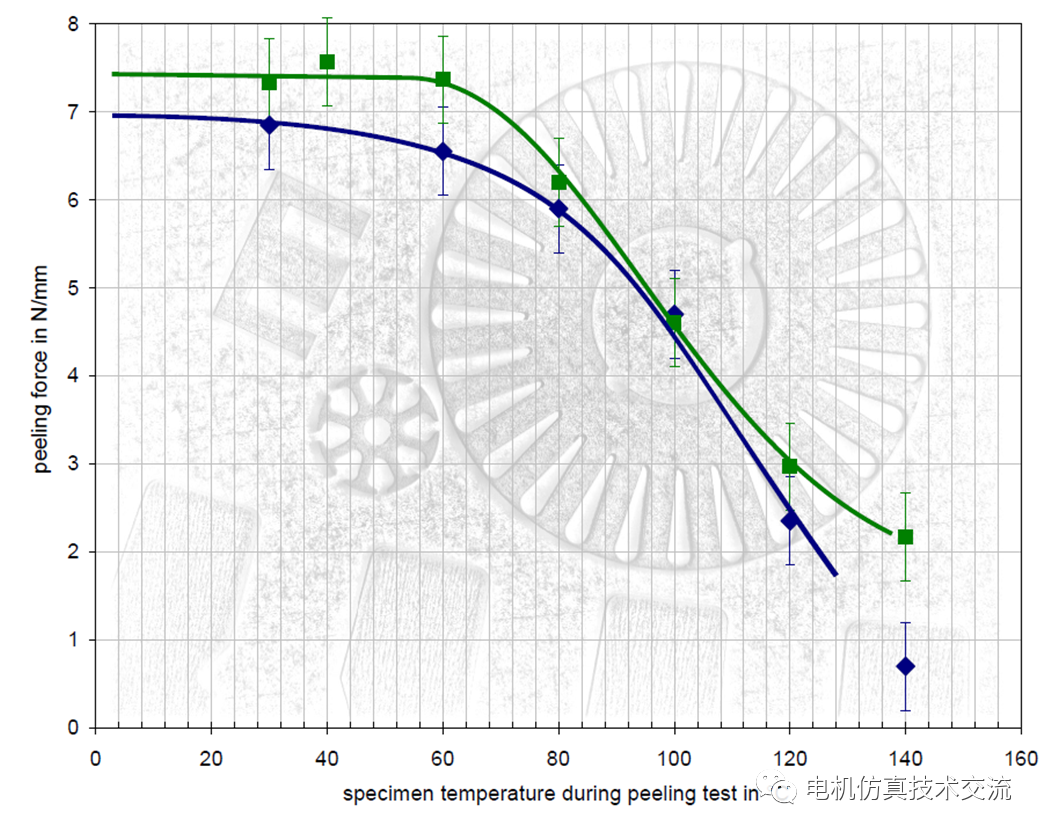

The strength curve of the T-peel test of a company at different temperatures

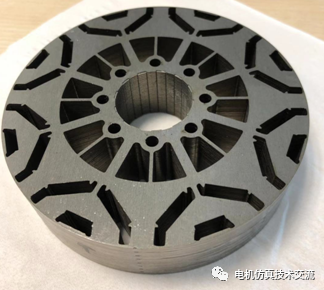

A company is working on self-adhesive rotor core

XINDA

XINDA