![]()

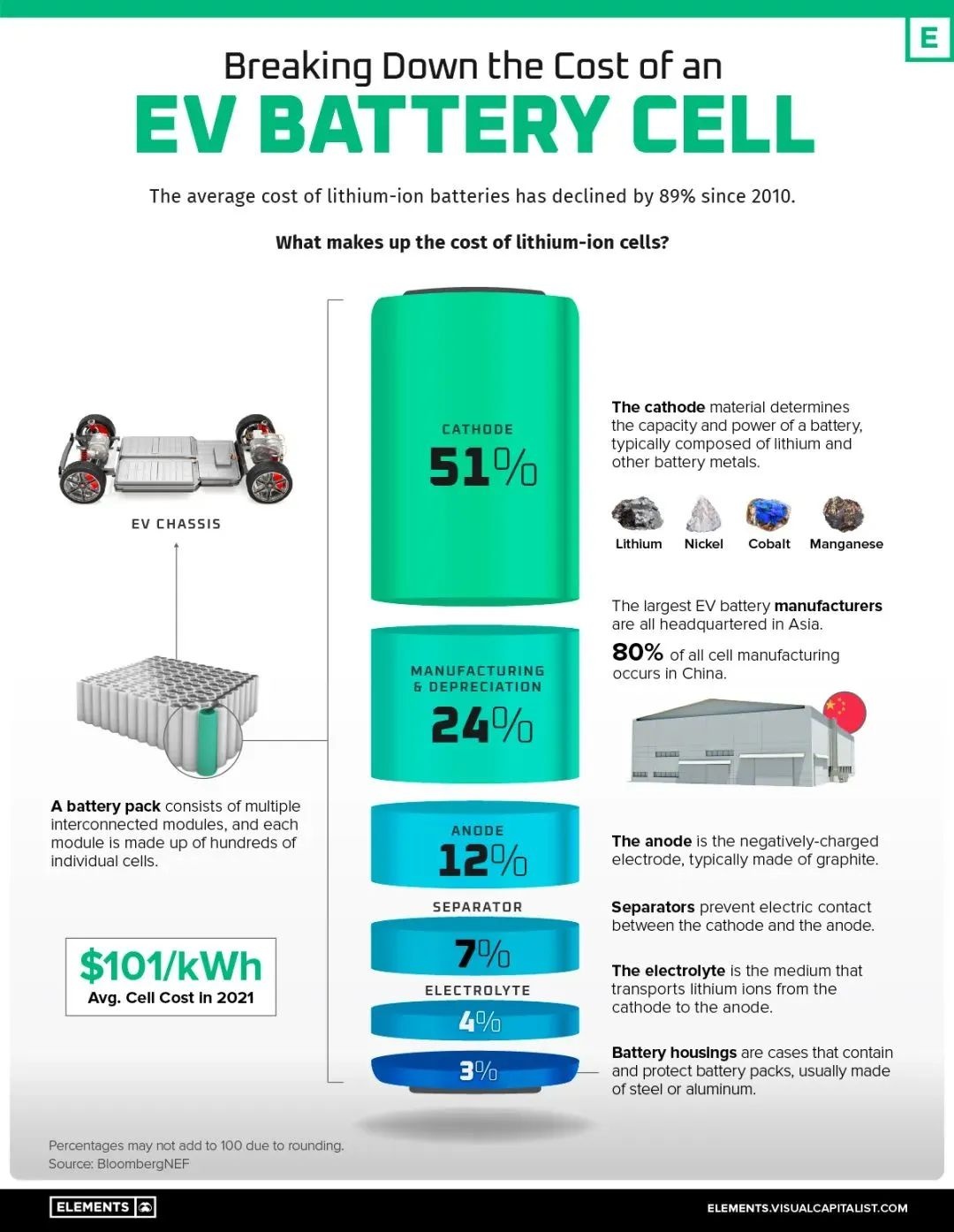

The Virtual Capitalist website released an infographic analyzing the cost of electric vehicle power batteriesAs the price of electric vehicle (EV) batteries continues to fall, the global supply of electric vehicles and the demand for their batteries are increasing. Since 2010, the average price of a lithium-ion EV battery pack has dropped from $1,200/kWh to $132/kWh. Inside each electric vehicle battery pack are multiple interconnected modules made up of tens to hundreds of rechargeable lithium-ion cells. Collectively, these cells account for about 77% of the total cost of an average battery pack, or about $101/kWh.

EV battery components as a percentage of total battery pack cost:

Why are cathodes so expensive?

The cathode is the positive terminal of the battery. When the battery discharges, both electrons and positively charged molecules (the namesake lithium ions) flow from the anode to the cathode, which stores both until the battery is charged again. This means that the cathode effectively determines the battery's performance, range and thermal safety, and thus the electric vehicle itself, making it one of the most important components. They are composed of various metals (in refined form), depending on the battery chemistry, often including lithium and nickel. Modern commonly used cathode components include:

The battery metal that makes up the cathode is in high demand, with automakers such as Tesla scrambling to secure supplies. In fact, the metal material in the cathode, as well as the metal materials in other parts of the battery, accounts for about 40% of the total cost of the battery.Components other than cathode account for 49% of battery costThe battery manufacturing process, which includes producing electrodes, assembling and finishing the cell, accounts for 24% of the total cost. The anode is another important component of the battery, accounting for 12 percent of the total cost and about a quarter of the cathode. The anodes of lithium-ion batteries are usually made of natural or synthetic graphite, which tends to be less expensive than other metallic materials.The heart of new energy vehicles - power battery

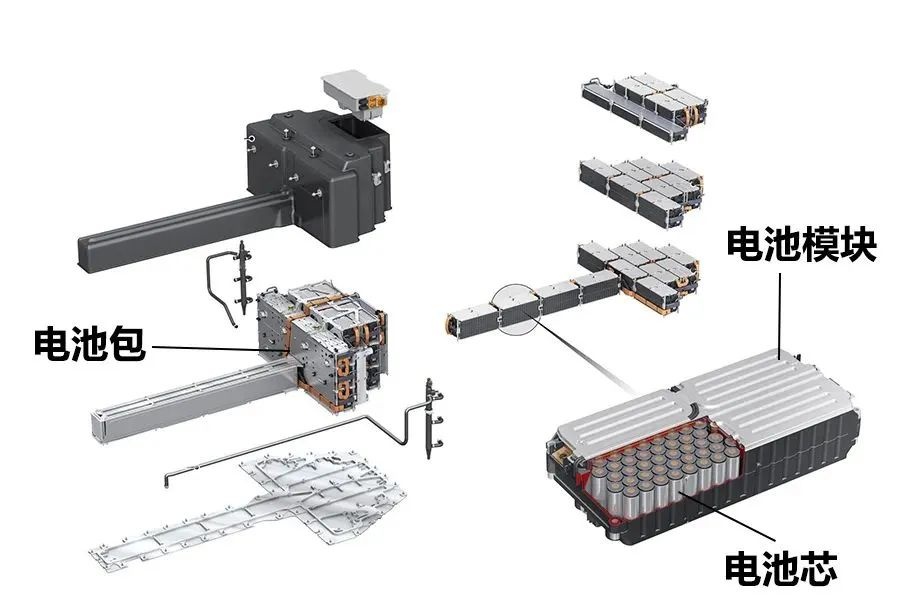

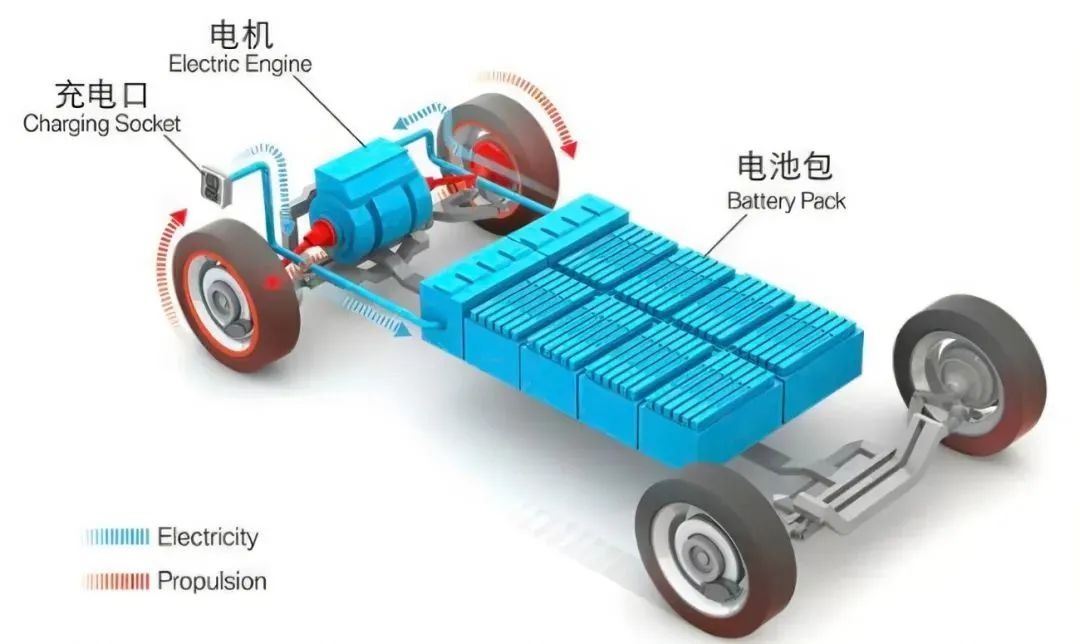

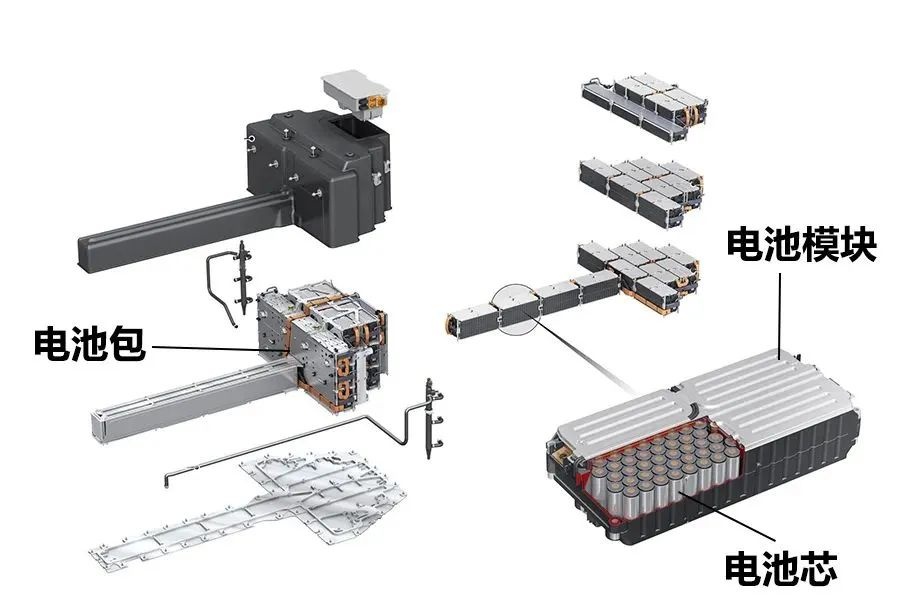

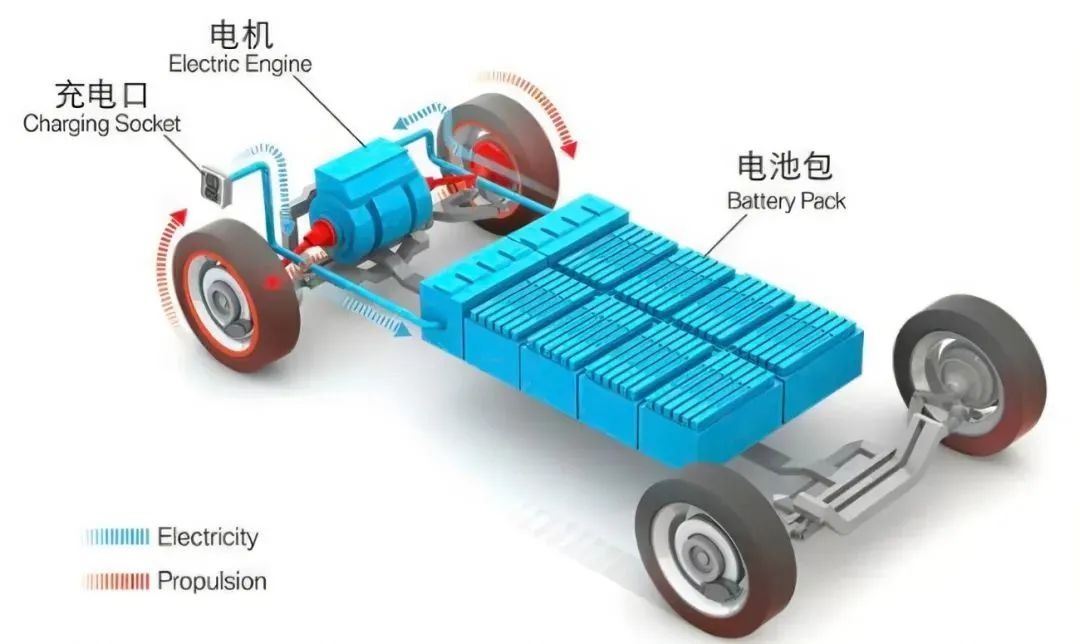

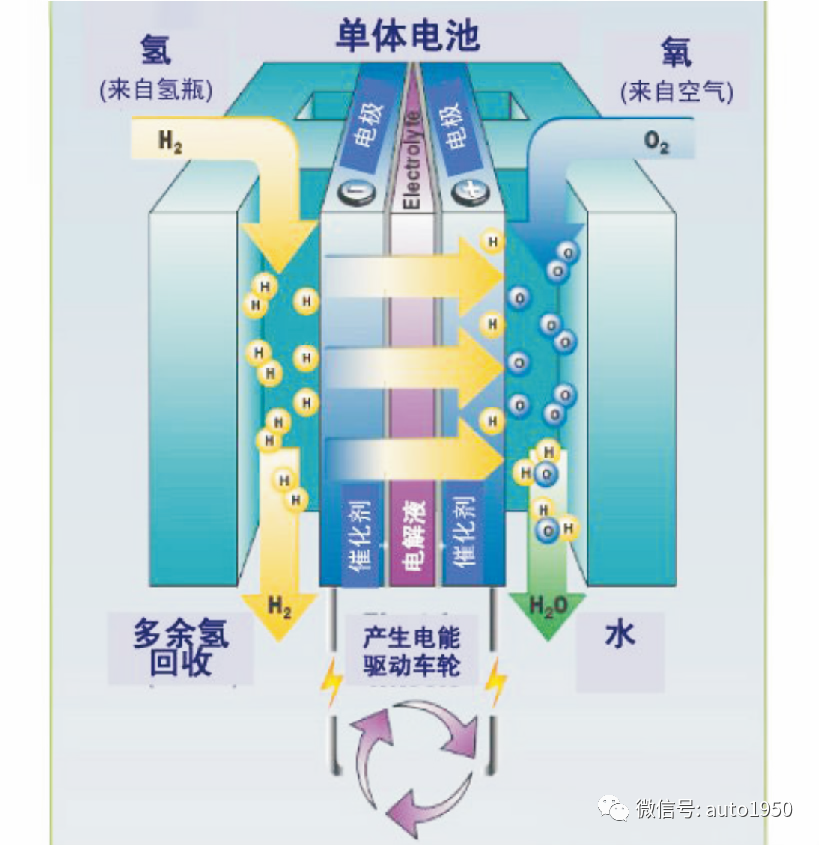

As the power source of new energy vehicles, the power battery is the most important system in the vehicle, accounting for 30% to 40% of the vehicle cost. This is also a symbolic component different from other traditional fuel vehicles. The heart of traditional fuel vehicles is the engine. The heart of new energy vehicles is the power battery.At present, due to the accidental safety accidents of new energy vehicles and the severe shortening of mileage in winter, there are doubts about the future development prospects of new energy vehicles. There are four main reasons: the mileage of new energy vehicles, the safety and convenience of power battery charging and Battery recycling.The editor of these four problems boils them down to one problem: the problem of power batteries.Therefore, is new energy vehicles a policy-oriented product, or a product that can replace fuel vehicles and meet the real needs of the market in the future? The key lies in whether it can solve the problem of power batteries?Structural composition of power batteryThe power battery is composed of several battery cells, CSC information collection system, battery management control unit (BMU), battery high voltage distribution unit, cooling system, etc.Automotive Power Battery UnitA battery cell is the smallest unit that constitutes a battery, consisting of a positive electrode, a negative electrode, and an organic electrolyte. The battery module is composed of several battery cells connected in parallel. By connecting several battery packs in series to form a battery unit, and then connecting several battery units in series, the power battery assembly can be formed. At present, the power battery loading on the market is mainly provided by ternary lithium batteries and lithium iron phosphate batteries, so let's focus on these two types of power batteries below.Power battery type - ternary lithium batteryTernary polymer lithium battery, referred to as ternary lithium battery, refers to a lithium battery that uses nickel-cobalt manganese oxide lithium (Li(NiCoMn)O2) or nickel-cobalt lithium aluminate as the positive electrode material. The ternary composite positive electrode material is Using nickel salt, cobalt salt, and manganese salt as raw materials, the ratio of nickel, cobalt, and manganese can be adjusted according to actual needs. The battery with ternary material as the positive electrode is safer than lithium cobalt oxide battery. Energy storage devices with integrated energy density and high voltage have been widely used in mobile and wireless electronic devices, power tools, hybrid and electric vehicles and other fields.The reason why ternary lithium batteries are favored by many car companies is mainly due to the high energy density of ternary lithium batteries. The greater the energy density, the more electricity stored in the unit volume or weight of the power battery.Generally speaking, the higher the energy density of the battery, the higher the battery life of pure electric vehicles. Therefore, for new energy car companies that are pursuing long battery life, the battery life advantage of ternary lithium batteries is very attractive. At the same time, ternary lithium batteries also have certain advantages in low temperature resistance. Under the same low temperature conditions, compared with other types of batteries, ternary lithium batteries have smaller power attenuation in winter and are more suitable for northern regions in cold winters.The disadvantage of ternary lithium batteries is that they are less stable. When the temperature reaches 250-350°C, they are prone to thermal runaway, and there is a high risk of spontaneous combustion during fast charging. Therefore, ternary lithium batteries have very strict requirements on heat dissipation. This also has higher technical requirements for the BMS battery management system.Power battery type - lithium iron phosphate batteryLithium iron phosphate battery is a lithium-ion battery that uses lithium iron phosphate (LiFePO4) as the positive electrode material and carbon as the negative electrode material. The rated voltage of the single cell is 3.2V. Its biggest advantage is high safety. At present, the thermal stability of lithium iron phosphate batteries is the best, and the thermal runaway temperature is generally above 500 degrees, and the risk of spontaneous combustion of batteries is very low. Secondly, the cycle life of the lithium iron phosphate battery is also relatively long, and it will not start to decay until the number of charge and discharge cycles is greater than 3,500, which is equivalent to 10 years. In addition, the price of lithium iron phosphate batteries also has a great advantage.Lithium iron phosphate battery has the advantages of high working voltage, high energy density, long cycle life, good safety performance, low self-discharge rate, and no memory effect.However, since the energy density of lithium iron phosphate batteries is not as high as that of ternary lithium batteries, the average energy density of the former is 130-140Wh/kg, and the average energy density of ternary lithium batteries is 160Wh/kg, so it is difficult to compete with ternary lithium batteries in terms of battery life. This is why there are few pure electric vehicles using lithium iron phosphate batteries.Power battery type—hydrogen fuel cellCompared with storage batteries, hydrogen fuel cells, which are very small at present, are truly "zero-emission" clean energy sources, which directly convert the chemical energy of hydrogen and oxygen into electrical energy generating devices. The basic principle is the reverse reaction of electrolyzing water. Hydrogen and oxygen are supplied to the cathode and anode respectively. After the hydrogen diffuses outward through the cathode and reacts with the electrolyte, electrons are released to reach the anode through an external load, and only water and heat are generated.

It can be said that the advantages of hydrogen fuel cells are not only reflected in the high energy conversion efficiency of the battery, but also no pollution and no noise. From a long-term perspective, hydrogen fuel cells will definitely be a key development direction of the power battery industry in the future. For example, Hyundai Motor recently announced a "2025 strategy". In addition to expanding the sales of pure electric vehicles, hydrogen fuel electric vehicles are also in its sales plan. In addition, well-known car companies such as Toyota and Honda are also actively promoting the development of hydrogen fuel cell technology.But at this stage, many problems of hydrogen fuel electric vehicles still cannot be effectively solved, the main reason is that the storage of hydrogen is inconvenient, and at the same time, the current cost is too high.The future development trend of power batteries is: the energy density is getting higher and higher, the charging speed is getting faster and faster, the safety is getting stronger, and the cost is getting lower and lower.

XINDA

XINDA